What performance testing does the finished PA12 nylon tube need to undergo?

After the finished

PA12 Fuel Pipe is produced, it does need to go through a series of performance tests to ensure that its quality and performance meet the requirements. The following are some common performance testing items:

We will conduct mechanical property testing. This includes testing of tensile strength, flexural strength, impact toughness and other indicators. These tests evaluate the performance of nylon tubing under stress to ensure it has sufficient strength and toughness during use.

Secondly, we will check the dimensional accuracy of the nylon tube. This includes the measurement of key dimensions such as the outer diameter, inner diameter, and wall thickness of the pipe. By comparing the deviation between the actual size and the standard size, we can determine whether the size of the nylon tube meets the requirements, thereby ensuring that it can be connected normally to other components or systems.

We also test the corrosion resistance of nylon tubing. This is because

Nylon Oil Pipe will be exposed to corrosive media in many application scenarios, so it is necessary to ensure that they have good corrosion resistance. We will simulate some common corrosive environments and observe the performance of PA12 nylon tubes in these environments to evaluate their corrosion resistance.

In addition to the above tests, we may also conduct other specific performance tests based on the specific application requirements of PA12 nylon tubes, such as high temperature resistance, low temperature resistance, wear resistance, etc. These tests are all to ensure that nylon tubes can maintain stable performance under various usage conditions.

How does PA12 nylon tube perform in terms of environmental protection and sustainability?

From the perspective of raw materials, PA12 nylon tube is processed from nylon 12 resin, and the material itself can be recycled and reused. This means that waste materials or used nylon tubes generated during production and use can be recycled and reused to reduce the impact on the environment.

During the production process of PA12 nylon tube, manufacturers will also take a series of environmental protection measures, such as optimizing the production process and reducing the emission of waste gas, waste water and solid waste. These measures help reduce the environmental load during production.

During the use of PA12 nylon tube, its excellent corrosion resistance, wear resistance and long-term stability enable it to reduce the waste of resources caused by frequent replacement of pipes. At the same time, due to its excellent physical properties,

Nylon Low-Pressure Oil Pipe can replace traditional metal pipes in many fields, thereby reducing the consumption and mining of metal resources.

Of course, we cannot ignore the potential environmental problems that may exist during the production and use of nylon tubes. For example, some additives in the production process may have certain impacts on the environment. Therefore, it is very important to choose nylon tube products with better environmental protection performance, as well as reasonable maintenance and management during use.

View More

PA12 Nylon Pipe Low-Pressure Oil Pipe Quick Plug Connector

PA12 nylon pipe low-pressure oil pipe quick-plug joints are suitable for light t...

View More

PA12 Nylon Pipe Low-Pressure Oil Pipe Quick Plug Connector

PA12 nylon pipe low-pressure oil pipe quick-plug joints are suitable for light t...  View More

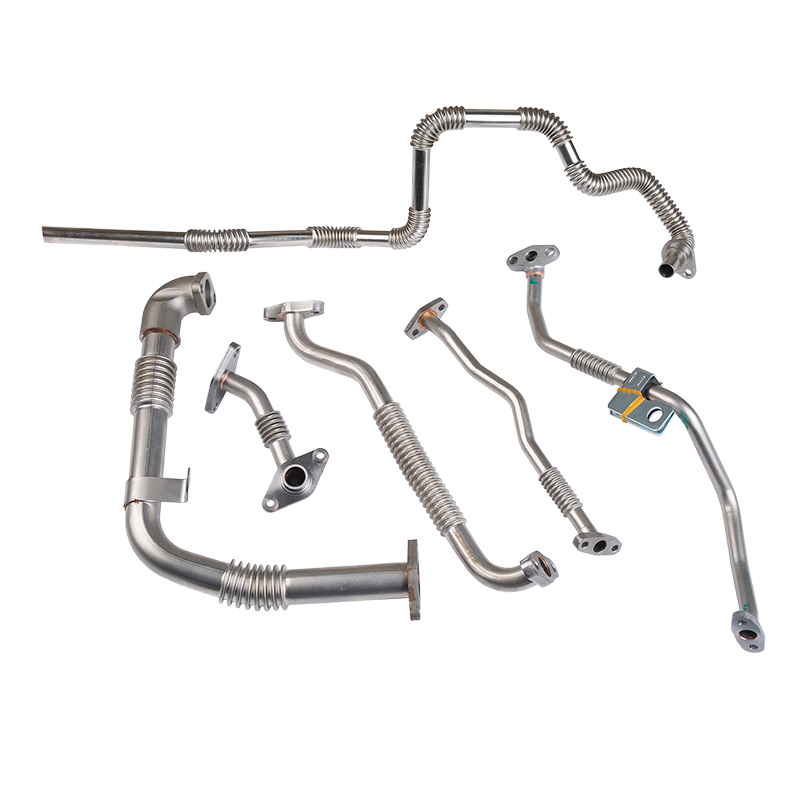

PA12 Material Engineering Machinery Special Fuel Return Pipe

PA12 material The special fuel return pipe for engineering machinery is made of ...

View More

PA12 Material Engineering Machinery Special Fuel Return Pipe

PA12 material The special fuel return pipe for engineering machinery is made of ...  View More

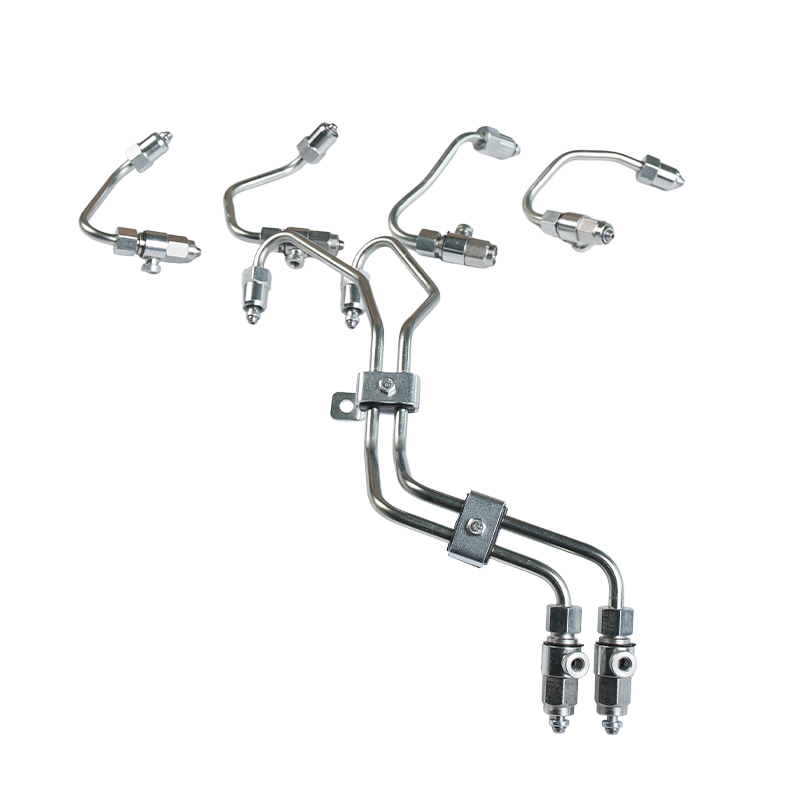

Light Truck Fuel Return Pipe

Light truck fuel return pipe is a key component suitable for engines of Cummins,...

View More

Light Truck Fuel Return Pipe

Light truck fuel return pipe is a key component suitable for engines of Cummins,...  View More

PA12 Nylon Tube Fuel Low Pressure Oil Pipe

PA12 nylon pipe is a fuel low-pressure oil pipe with performance and is widely u...

View More

PA12 Nylon Tube Fuel Low Pressure Oil Pipe

PA12 nylon pipe is a fuel low-pressure oil pipe with performance and is widely u...

English

English Español

Español русский

русский