Low pressure oil hoses are essential components in hydraulic systems, machinery, and automotive applications. They are designed to transport oil or other fluids at relatively low pressures while maintaining flexibility and durability. A common question from engineers, technicians, and equipment users is: Can the low pressure oil hose be bent? The answer is yes, but there are important considerations regarding bend radius, material properties, installation, and safety.

Understanding Low Pressure Oil Hoses

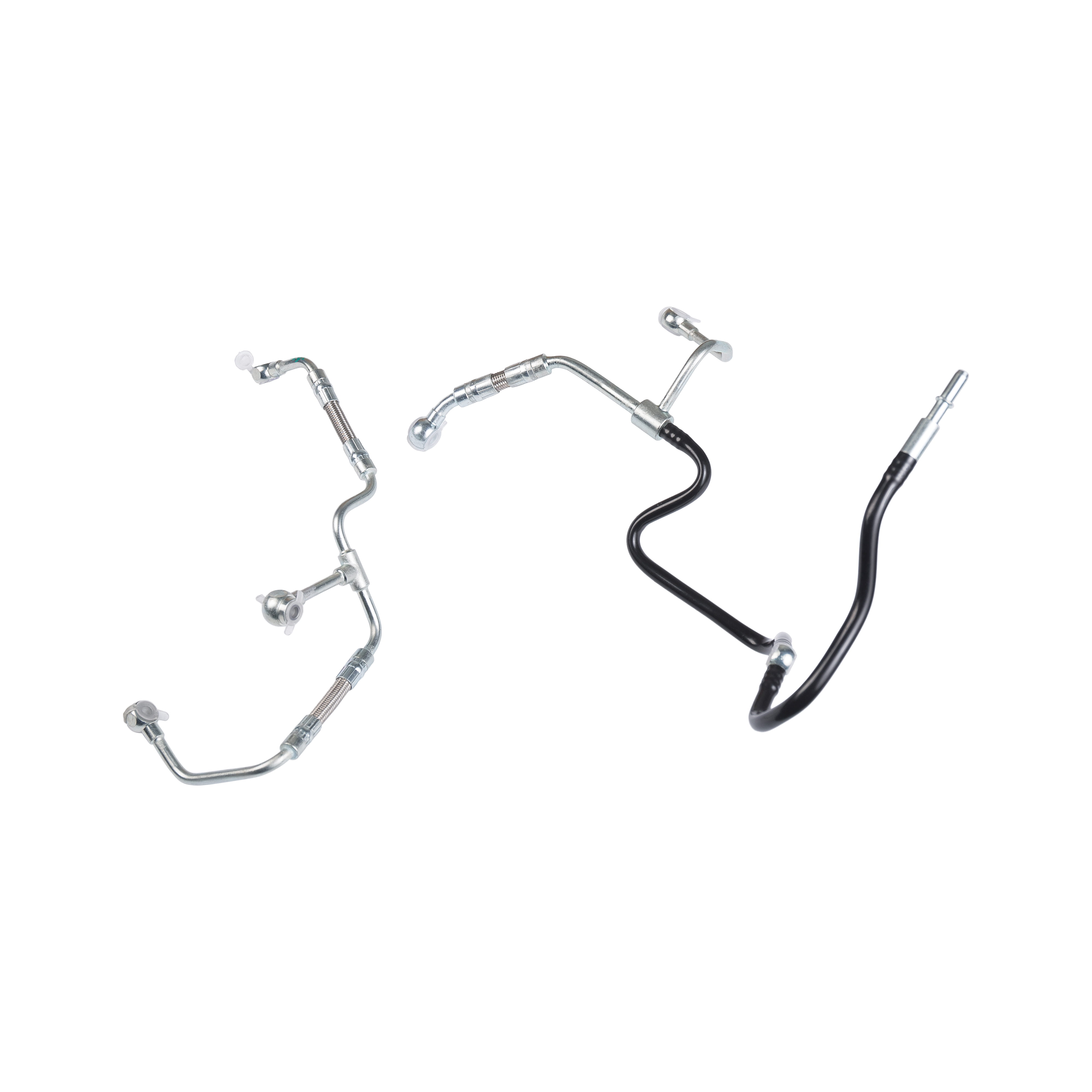

Low pressure oil hoses are typically made from materials such as synthetic rubber, PVC, or reinforced polymer composites. They are reinforced with braided fibers or textile layers to provide additional strength and prevent kinking under pressure. Unlike high-pressure hoses, which are rigid and have strict bending limitations, low pressure hoses are designed to be more flexible and easier to route through complex machinery or tight spaces.

Flexibility and Bend Radius

The ability to bend a low pressure oil hose depends largely on its bend radius, which is the minimum radius the hose can be bent without damaging it or reducing its performance. Exceeding this minimum radius can cause:

- Kinking: The hose collapses or folds, restricting fluid flow.

- Cracking or Weakening: The hose material may crack or degrade at the bend.

- Reduced Lifespan: Frequent sharp bends can accelerate wear.

Manufacturers typically specify the minimum bend radius in the product datasheet. For low pressure hoses, this radius is generally small compared to high-pressure hoses, allowing for greater flexibility during installation.

Material Considerations

The hose material plays a crucial role in how easily it can be bent.

- Rubber Hoses: Rubber is naturally flexible and can withstand moderate bending. Reinforced rubber hoses are stronger and resist kinking.

- PVC Hoses: PVC hoses are lightweight and flexible, but they may be more prone to kinking if bent too sharply.

- Reinforced Hoses: Hoses with textile or fiber reinforcement maintain their shape better under bending stress, reducing the risk of collapse.

Choosing the right material ensures that the hose can be bent safely without compromising flow or structural integrity.

Installation Tips for Bending

When bending a low pressure oil hose, follow these best practices to maintain performance and longevity:

- Avoid Sharp Bends: Always respect the manufacturer’s minimum bend radius. Use smooth curves rather than tight angles.

- Use Hose Supports or Guides: Proper routing prevents the hose from rubbing against surfaces or being pinched.

- Allow for Expansion: Hoses can expand slightly under pressure; ensure that bends do not restrict this movement.

- Check Connections: Ensure that fittings and connectors are properly aligned to prevent stress at the hose ends.

Following these installation guidelines helps prevent leaks, kinking, and premature failure.

Applications Where Bending Is Common

Low pressure oil hoses are used in various applications where bending is necessary:

- Automotive Systems: Fuel lines, oil lines, and lubrication systems often require hoses to navigate tight engine compartments.

- Hydraulic Equipment: Industrial machinery uses flexible hoses to connect moving parts without rigid piping.

- Agricultural Machinery: Tractors, harvesters, and other equipment rely on hoses that bend and move with machine components.

- Marine Applications: Boats and ships use flexible low pressure hoses for engine lubrication and fuel systems.

In all these scenarios, proper bending ensures smooth fluid flow while accommodating the movement and layout of machinery.

Maintenance Considerations

Even though low pressure oil hoses are bendable, routine inspection is essential to maintain safety and performance:

- Look for Kinks or Cracks: Check areas where the hose bends frequently.

- Inspect for Leaks: Ensure that bends have not compromised the hose’s integrity.

- Replace Worn Hoses: Hoses showing signs of wear, cracking, or deformation should be replaced promptly.

Routine maintenance extends hose lifespan and prevents unexpected equipment failures.

Safety and Performance

Bending a low pressure oil hose improperly can cause safety hazards, including fluid leaks, equipment malfunction, and environmental contamination. Ensuring that bends are gradual, hoses are properly supported, and materials are suitable for the application helps maintain system efficiency and safety.

Conclusion

So, can the low pressure oil hose be bent? Yes, it can be bent, provided that the minimum bend radius, material properties, and proper installation techniques are respected. Low pressure hoses are designed for flexibility, making them ideal for routing through complex machinery or tight spaces.

However, bending beyond the recommended limits can lead to kinking, leaks, and reduced lifespan. Choosing the right hose material, following manufacturer guidelines, and performing regular inspections are essential practices for safe and efficient operation.

In summary, low pressure oil hoses are versatile and bendable components that balance flexibility and durability. With careful handling and proper installation, they can navigate tight spaces and moving machinery without compromising performance, making them a reliable choice for automotive, industrial, agricultural, and marine applications.

English

English Español

Español русский

русский