-

View More

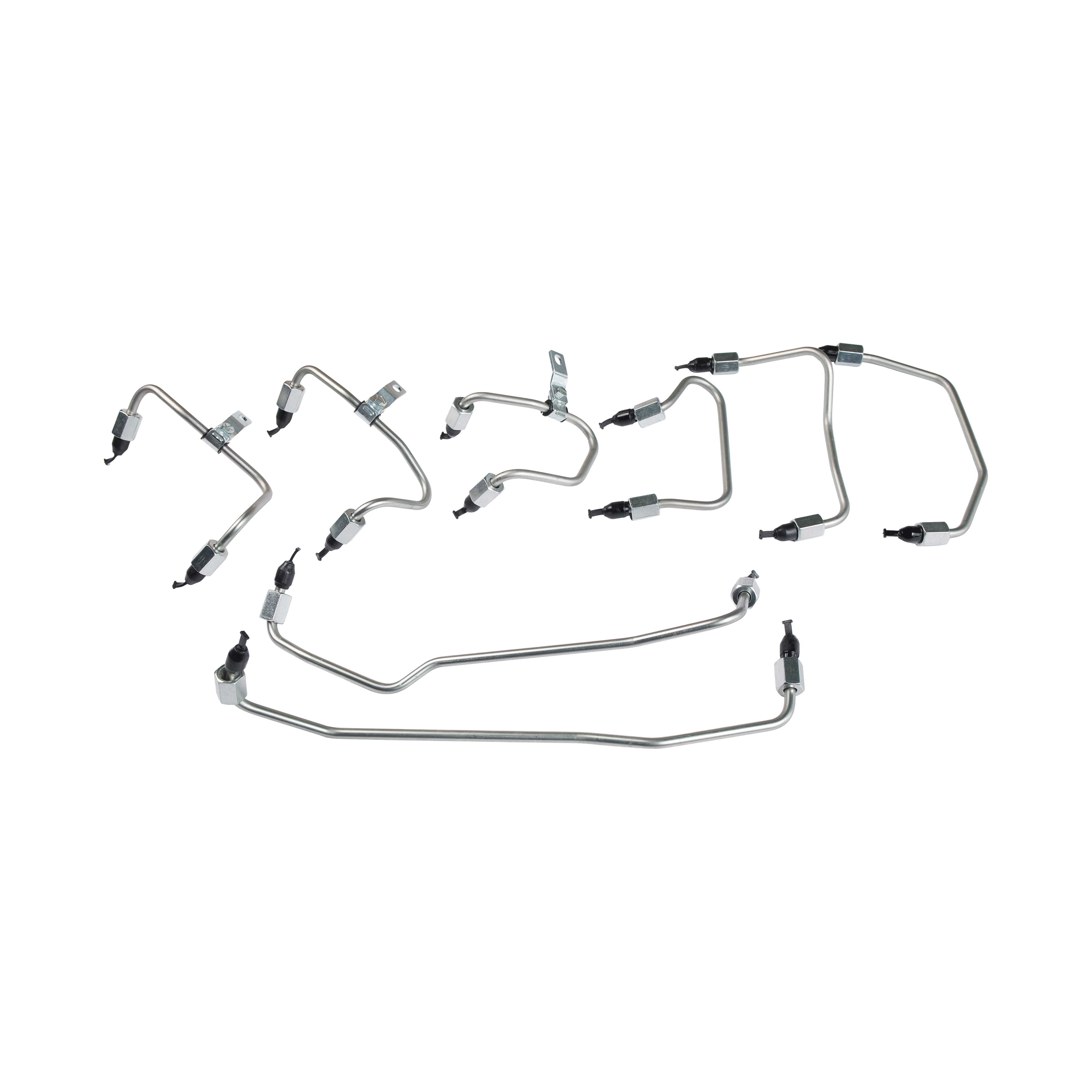

1800 Bar Special Internal Combustion Engine Fuel Injection High-Pressure Oil Pipe For Marine Engines

The special high-pressure oil pipe for ship engines adopts a double-layer struct...

View More

1800 Bar Special Internal Combustion Engine Fuel Injection High-Pressure Oil Pipe For Marine Engines

The special high-pressure oil pipe for ship engines adopts a double-layer struct... -

View More

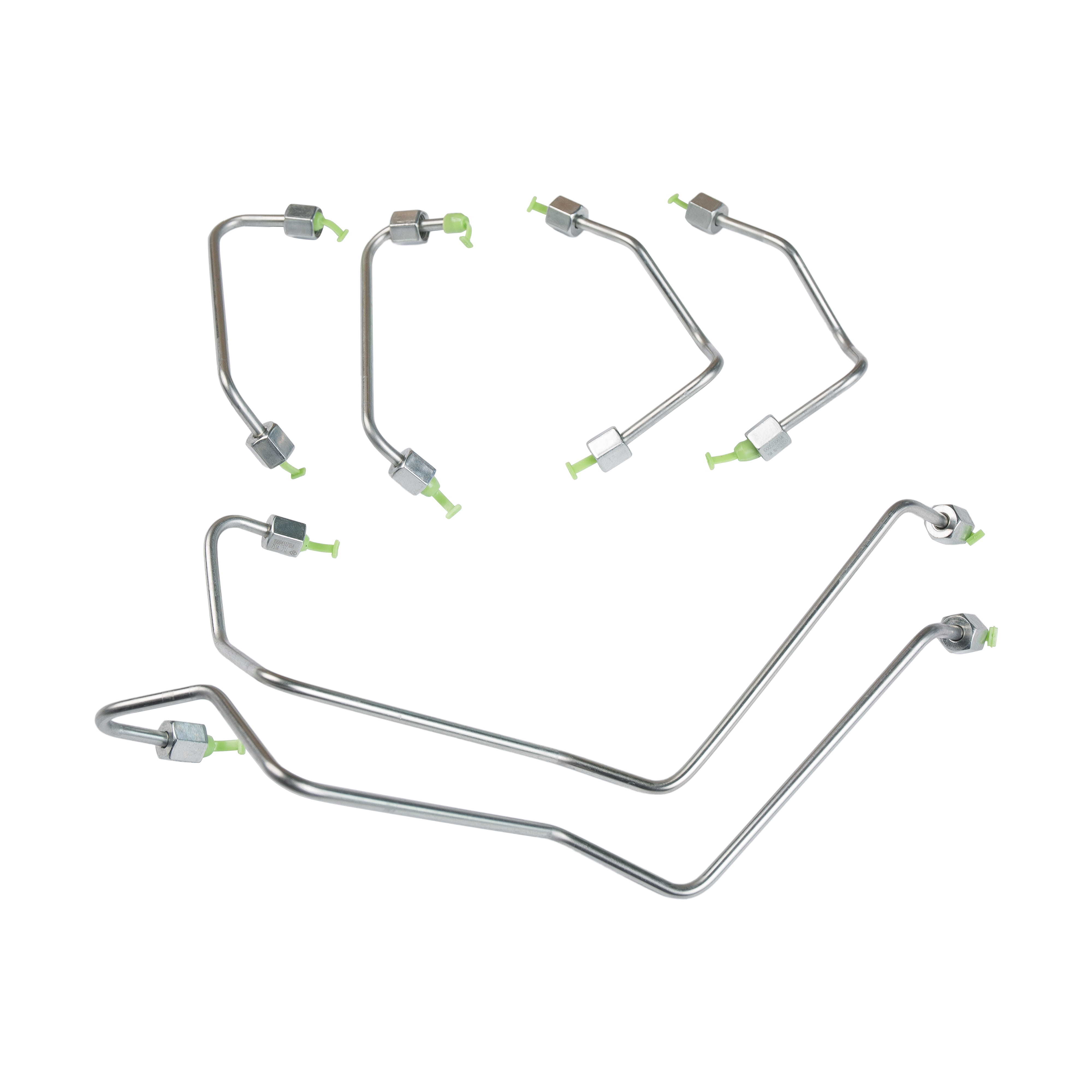

1800 Bar Special Sany Power Heavy Trucks High-Pressure Oil Pipe

Special for heavy trucks, Sany Power, system pressure: 1800 bar

Sany Heavy Truck...

View More

1800 Bar Special Sany Power Heavy Trucks High-Pressure Oil Pipe

Special for heavy trucks, Sany Power, system pressure: 1800 bar

Sany Heavy Truck... -

View More

1200 Bar High-Power Generator Set Special High-Pressure Oil Pipe

Special for high-horsepower generator sets, system pressure: 1200 bar

For high-p...

View More

1200 Bar High-Power Generator Set Special High-Pressure Oil Pipe

Special for high-horsepower generator sets, system pressure: 1200 bar

For high-p... -

View More

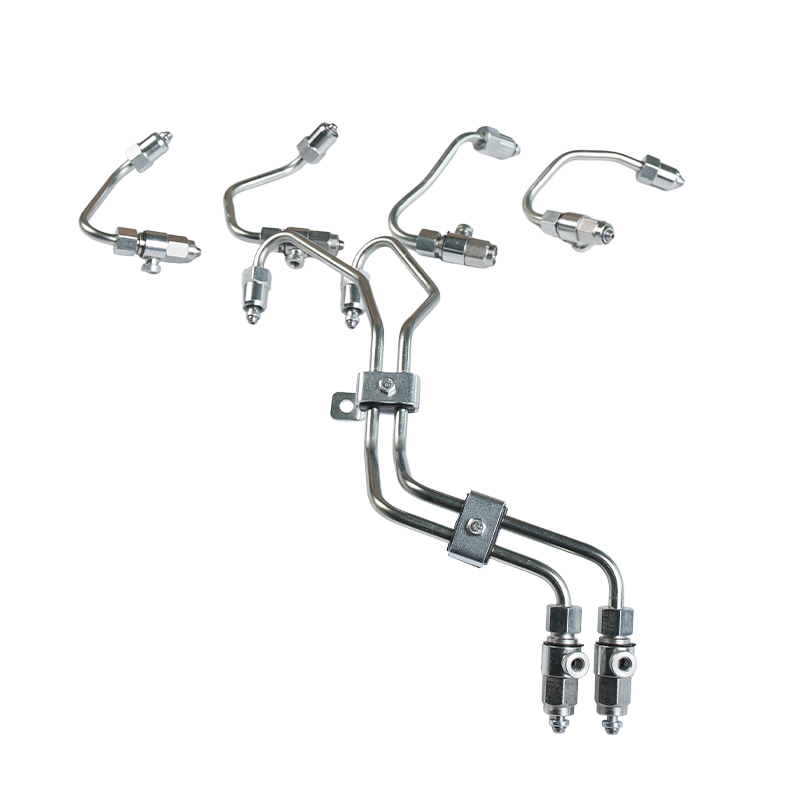

Cummins Power High-Pressure Oil Pipe For Light Trucks

Special for light trucks, Cummins power, system pressure: 1600 bar, 1800 bar

Cum...

View More

Cummins Power High-Pressure Oil Pipe For Light Trucks

Special for light trucks, Cummins power, system pressure: 1600 bar, 1800 bar

Cum... -

View More

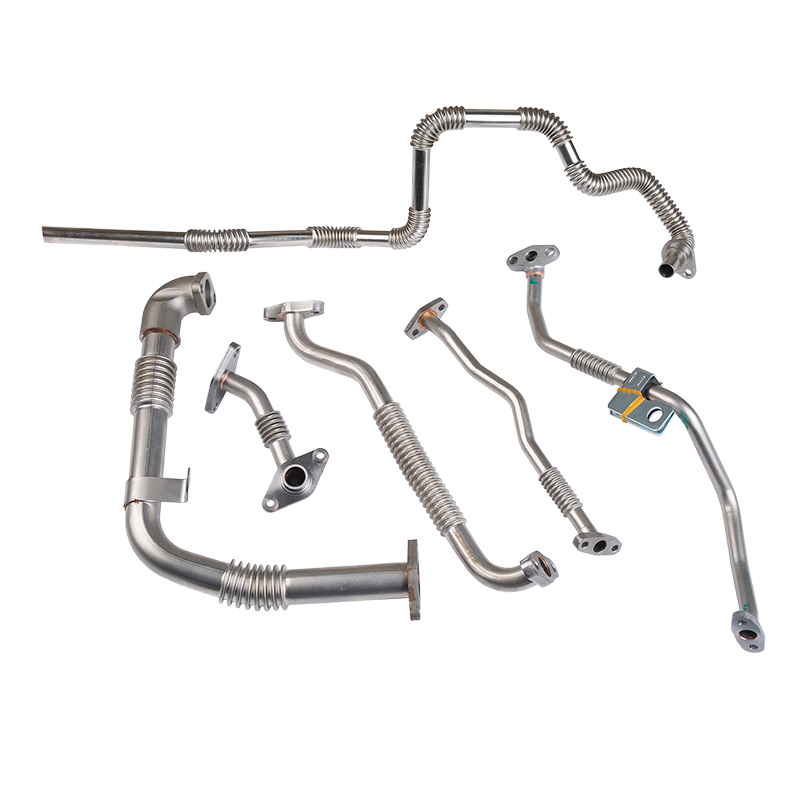

Hino Power Injection High-Pressure Oil Pipe For Light Trucks

Special for light trucks, Hino Power, system pressure: 1600 bar, 1800 bar

We pro...

View More

Hino Power Injection High-Pressure Oil Pipe For Light Trucks

Special for light trucks, Hino Power, system pressure: 1600 bar, 1800 bar

We pro... -

View More

Light Trucks Special Diesel Power Injection High-Pressure Oil Pipe

Special for light trucks, Shangchai Power, system pressure: 1600 bar, 1800 bar

T...

View More

Light Trucks Special Diesel Power Injection High-Pressure Oil Pipe

Special for light trucks, Shangchai Power, system pressure: 1600 bar, 1800 bar

T... -

View More

Weichai Power Light Trucks High-Pressure Oil Pipe

Special for light trucks, Weichai Power, system pressure: 1600 bar, 1800 bar

We ...

View More

Weichai Power Light Trucks High-Pressure Oil Pipe

Special for light trucks, Weichai Power, system pressure: 1600 bar, 1800 bar

We ... -

View More

1200 Bar High-Horsepower Agricultural Machinery Special Injection High-Pressure Oil Pipe

Special for high-horsepower agricultural machinery, system pressure: 1200 bar

Th...

View More

1200 Bar High-Horsepower Agricultural Machinery Special Injection High-Pressure Oil Pipe

Special for high-horsepower agricultural machinery, system pressure: 1200 bar

Th... -

View More

Isuzu Power Light Trucks High-Pressure Oil Pipe

Special for light trucks, Isuzu Power, system pressure: 1600 bar, 1800 bar

We pr...

View More

Isuzu Power Light Trucks High-Pressure Oil Pipe

Special for light trucks, Isuzu Power, system pressure: 1600 bar, 1800 bar

We pr... -

View More

Korean Doosan Engineering Machinery Professional High-Pressure Oil Pipe

Doosan Engineering Machinery Major in South Korea, system pressure: 1200 bar

Ten...

View More

Korean Doosan Engineering Machinery Professional High-Pressure Oil Pipe

Doosan Engineering Machinery Major in South Korea, system pressure: 1200 bar

Ten... -

View More

1000 Bar Kubota Construction Machinery Special High-Pressure Oil Pipe

Special for Kubota construction machinery, system pressure: 1000 bar

Kubota's sp...

View More

1000 Bar Kubota Construction Machinery Special High-Pressure Oil Pipe

Special for Kubota construction machinery, system pressure: 1000 bar

Kubota's sp... -

View More

1000 Bar Kubota Agricultural Machinery Special High Pressure Oil Pipe

Special for Kubota agricultural machinery, system pressure: 1000 bar

Kubota's sp...

View More

1000 Bar Kubota Agricultural Machinery Special High Pressure Oil Pipe

Special for Kubota agricultural machinery, system pressure: 1000 bar

Kubota's sp...

INQUIRE NOW

-

Language

-

+86 18958025210

-

wmxsb@hz-aojia.com

English

English Español

Español русский

русский