1. Basic definition and composition of low-pressure oil pipe

Engine Low-Pressure Oil Pipe is an important part of the fuel supply system, which is mainly responsible for transporting fuel from the fuel tank to the fuel pump or the front end of the engine fuel supply system. Its working pressure is usually between 0.3 and 0.5 MPa. Compared with the high-pressure oil pipe, it bears lower pressure, but its stability and sealing are crucial to the normal operation of the entire fuel system.

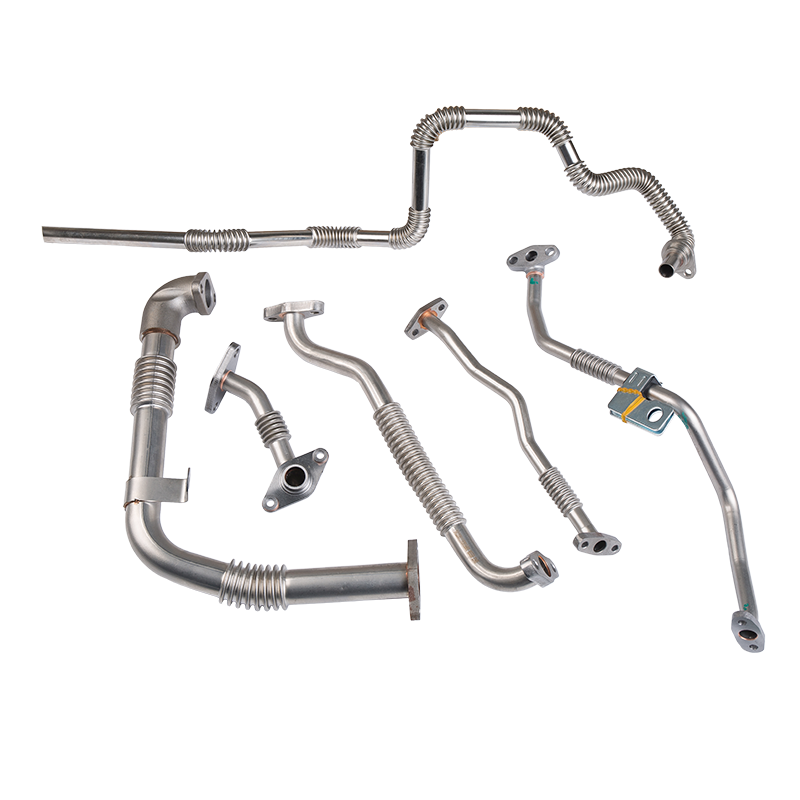

Low-pressure oil pipes are generally composed of metal pipes or oil-resistant rubber hoses, and the connecting parts include joints, clamps, etc. to ensure the sealing and firmness of the oil circuit.

2. Core functions of low-pressure oil pipes

Basic channel for fuel transmission

As the first section of the fuel delivery pipeline from the fuel tank to the fuel pump, the low-pressure oil pipe undertakes the basic fuel supply task. Its smoothness directly affects whether the fuel can smoothly enter the high-pressure pump or the front end of the injector.

Maintain the stability of the fuel system

During the fuel circulation process, the low-pressure oil pipe needs to maintain a constant oil pressure and flow to prevent uneven engine fuel supply due to oil pressure fluctuations, thereby affecting the starting performance, idling stability and power output.

Auxiliary fuel filtration and cooling

In some vehicle designs, the low-pressure oil circuit also bears the function of returning oil, sending excess fuel back to the fuel tank through reflux, taking away some heat at the same time, playing a certain cooling role, and assisting the fuel filter to complete the initial filtration.

3. The impact of low-pressure oil pipes on engine performance

Affecting engine start and operation

If the low-pressure oil pipe is blocked, leaking or aging, it will lead to insufficient fuel supply, causing engine start difficulty, flameout, shaking or even unable to run.

Relationship with fuel economy performance

Stable low-pressure fuel supply helps the fuel pump work efficiently, reduces unnecessary energy loss, and thus improves the fuel economy of the whole vehicle.

Affecting emissions and environmental performance

Poor fuel delivery may cause incomplete combustion, increase the emission of harmful substances in exhaust gas, and affect the compliance of vehicle emission standards.

4. Common problems and maintenance suggestions for low-pressure oil pipes

Common fault types

Aging and cracking of oil pipes: rubber materials are prone to hardening and cracking after long-term use.

Interface oil leakage: poor sealing at the connection or loose clamps.

Internal blockage: impurity deposition or poor fuel quality leads to poor circulation.

Daily maintenance suggestions

Regularly check whether the oil pipe has deformation, cracks or oil leakage.

When replacing the fuel filter, check the low-pressure oil circuit status simultaneously.

Use regular brand fuel to reduce the damage of impurities to the oil circuit.

Although the low-pressure oil pipe does not directly participate in the combustion process like the high-pressure oil pump or fuel injector, it plays the role of a "bridge" in the entire fuel system and is a key link to ensure smooth fuel delivery and maintain stable engine operation. With the development of automobile technology, the design of low-pressure oil pipes is also constantly optimized to adapt to more complex working environments and higher environmental protection requirements. Therefore, in engine maintenance and troubleshooting, the role of low-pressure oil pipes cannot be ignored.

English

English Español

Español русский

русский