In modern automobile engine systems, Seamless Carbon Steel Engine Low Pressure Pipe plays an important role in transporting fuel, lubricating oil or coolant. These pipes usually work under complex conditions of high temperature, high pressure and frequent vibration, which places extremely high demands on material performance and structural design. So, how do these pipes maintain stable operation in such harsh environments? Its stability mainly depends on the following aspects.

1. Material selection: Combination of high strength and heat resistance

Seamless carbon steel pipes are made of high-quality carbon steel, with high tensile strength and yield limit, and can maintain structural integrity under continuous pressure. At the same time, carbon steel materials have good thermal stability and are not easy to soften or deform in the operating temperature range of 150–300°C.

In addition, by adding trace alloying elements (such as chromium, molybdenum, etc.), its oxidation resistance and creep resistance can be further improved, the service life can be extended, and the needs of long-term operation of the engine can be met.

2. Seamless structure design: Eliminate the hidden dangers of welding defects

Compared with ordinary welded pipes, seamless carbon steel pipes do not undergo welding processes during the manufacturing process, avoiding defects such as pores, slag inclusions, and unfused welds that may exist at the weld. This one-piece structure greatly improves the sealing and overall strength of the pipe body, and is especially suitable for engine environments with vibration and pulsating pressure.

The seamless structure can also effectively prevent the expansion of fatigue cracks caused by local stress concentration, thereby improving the reliability of the system.

3. Surface treatment and anti-corrosion technology

Under high temperature and high pressure environments, corrosion is one of the key factors affecting the life of pipelines. For this reason, seamless carbon steel low-pressure pipes usually undergo a series of surface treatments, such as:

Galvanizing or nickel plating: improve corrosion resistance;

Phosphating: enhance rust resistance;

Coating with high temperature resistant coatings: such as silicone resin or ceramic coatings to isolate high temperature gases and chemical media.

These measures not only improve the durability of the pipeline, but also reduce the risk of leakage caused by corrosion.

4. Precision manufacturing and strict testing standards

In order to ensure stability under extreme conditions, seamless carbon steel pipes must follow strict process standards during the manufacturing process, including:

Precisely control wall thickness tolerance;

Ensure that the inner and outer surfaces are smooth and defect-free;

Perform hydraulic tests, air tightness tests and burst tests;

Perform fatigue tests that simulate the actual working conditions of the engine.

These quality control measures ensure that each pipe can meet the high standards of the engine system.

5. Installation and connection methods that adapt to complex working conditions

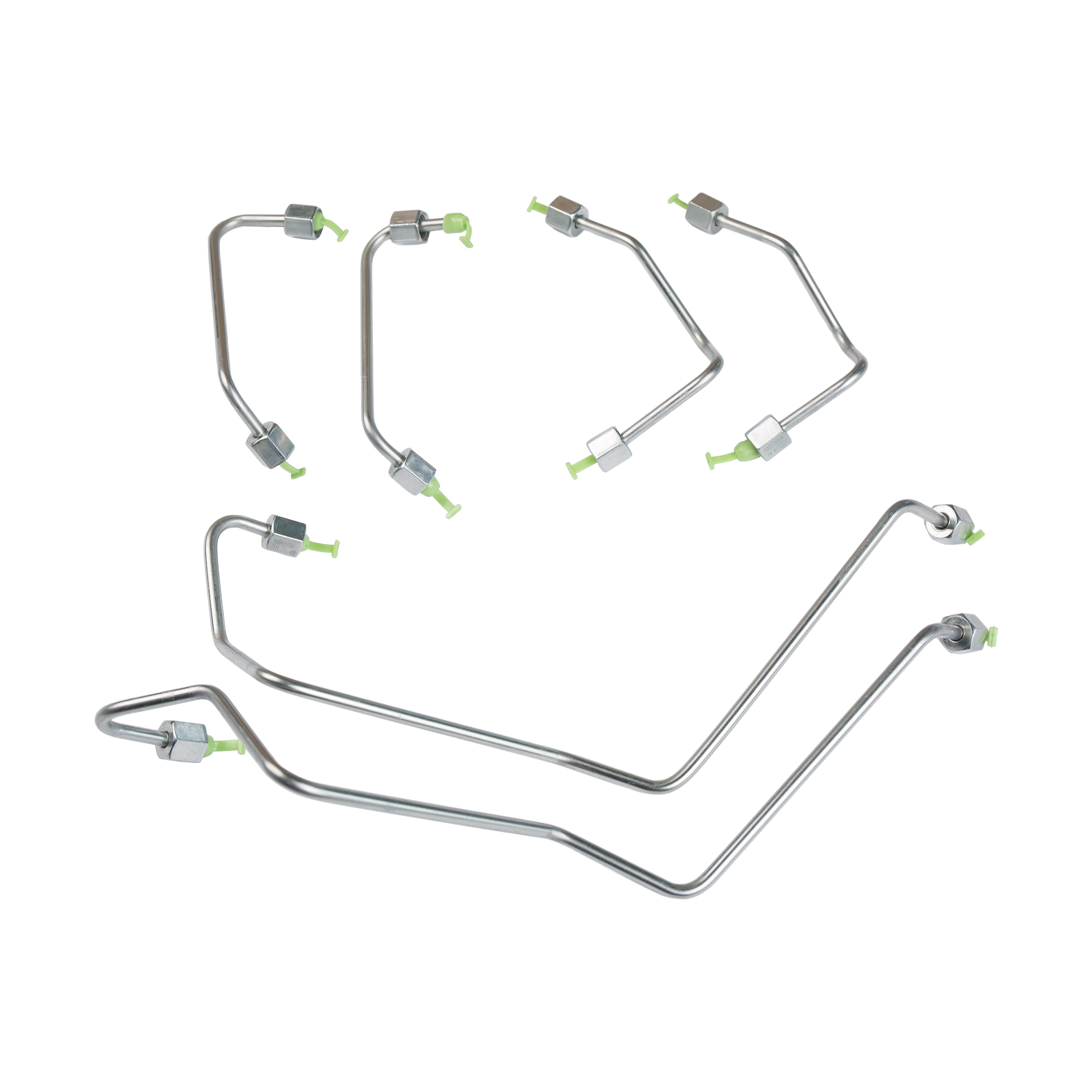

In the engine compartment, the space is small and the pipe layout is complex, so seamless carbon steel low-pressure pipes often use ferrule, flared or O-ring sealing structures to ensure that the connection parts still have good sealing and shock resistance under high temperature and high pressure.

Some high-end models will also use flexible bellows section design to absorb the mechanical vibration generated when the engine is running, reduce stress concentration, and thus improve the stability of the entire system.

The reason why seamless carbon steel engine low-pressure pipes can maintain stable operation under high temperature and high pressure environments is due to their excellent material properties, seamless structural design, advanced surface treatment technology and precision manufacturing process. As engines develop towards high efficiency, energy saving and lightweight, this type of pipe will continue to be upgraded in terms of lightweight and high-strength materials, intelligent monitoring integration, etc. in the future, providing stronger support for the safe and reliable operation of automotive power systems.

English

English Español

Español русский

русский