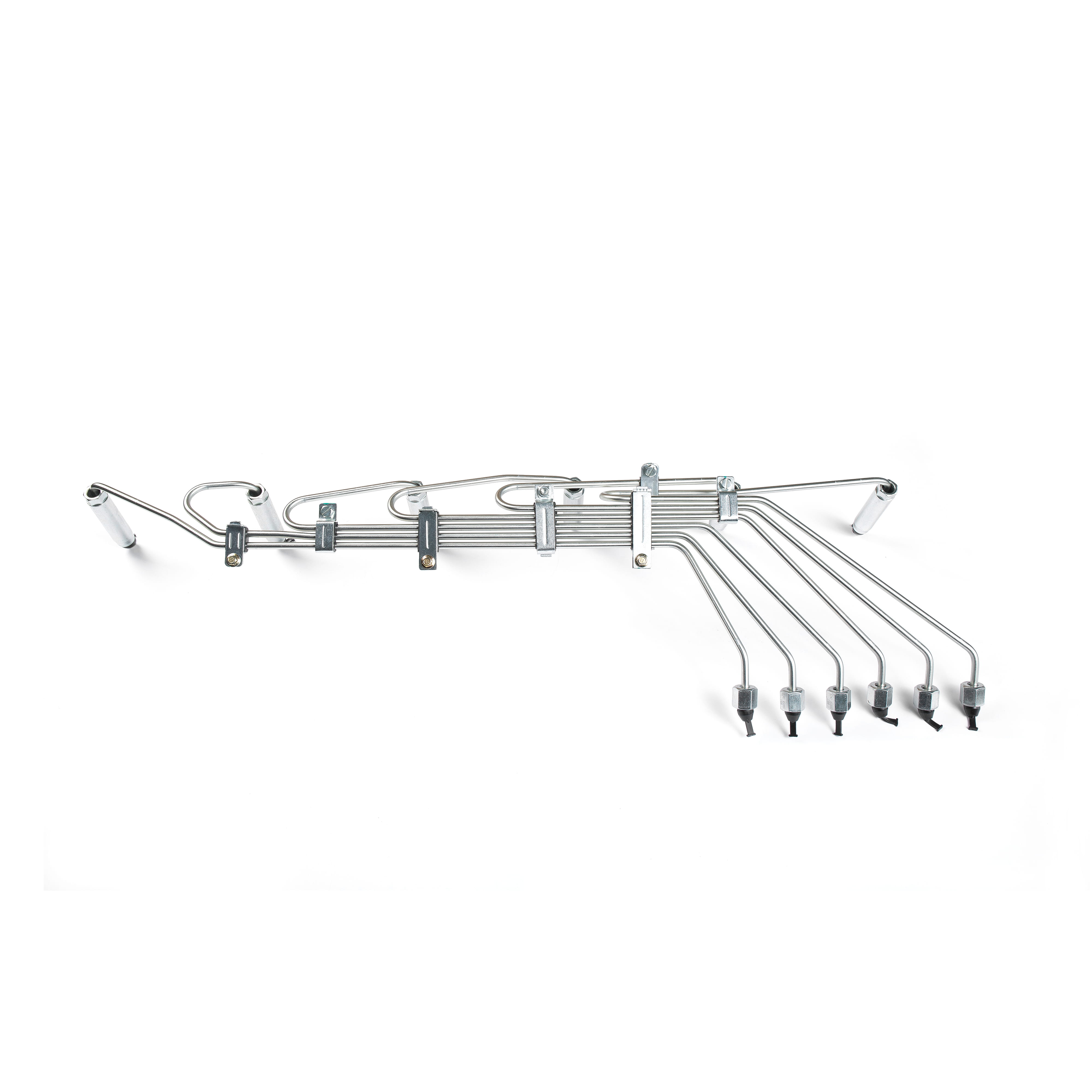

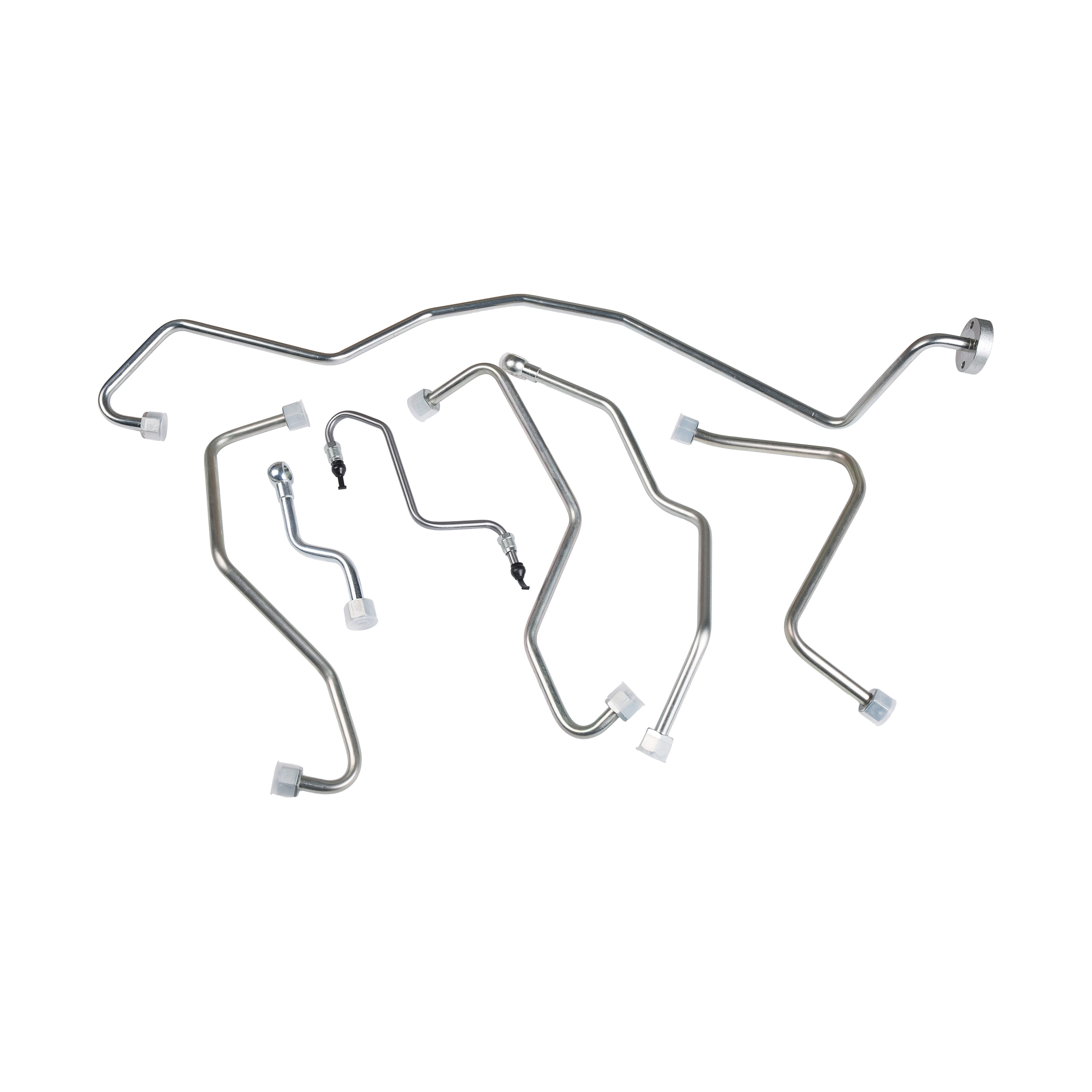

1. What is a Seamless Carbon Steel Engine Low Pressure Pipe?

A Seamless Carbon Steel Engine Low Pressure Pipe is a cylindrical hollow steel product designed to carry fluids or gases under relatively low pressure within engine systems and industrial setups. As the name suggests, it is made from carbon steel and produced using a seamless manufacturing process — meaning there are no welded joints along its length. This results in superior strength, reliability, and corrosion resistance compared to welded pipes, making it ideal for use in automotive engines, hydraulic systems, and low-pressure fuel or oil pipelines.

These pipes are typically employed where consistent pressure and temperature stability are essential. The seamless structure eliminates weak points that could otherwise cause leakage or rupture, ensuring a long and efficient service life in demanding environments.

2. Manufacturing Process of Seamless Carbon Steel Low Pressure Pipe

The production of seamless carbon steel pipes involves multiple precision-engineering steps to ensure the product meets strict dimensional and mechanical standards. Below is a simplified breakdown of the manufacturing process.

2.1 Raw Material Preparation

High-quality carbon steel billets are selected as the raw material. The carbon content typically ranges between 0.2% and 0.3%, which balances strength and ductility. Billets undergo descaling and inspection before heating.

2.2 Piercing and Elongation

Heated billets are pierced using a rotary piercing mill to form a hollow shell. This is then elongated and reduced in thickness using a mandrel mill or plug mill to achieve the desired diameter and wall thickness. The process maintains a seamless interior and exterior surface.

2.3 Heat Treatment

To enhance mechanical performance and remove internal stresses, the pipe undergoes controlled heat treatment processes such as normalizing or annealing. This step improves toughness, flexibility, and corrosion resistance.

2.4 Finishing and Inspection

After rolling and heat treatment, the pipes are straightened, cut to length, and surface-finished. Dimensional accuracy and surface integrity are verified through ultrasonic, hydrostatic, and visual testing. Only pipes that meet standard criteria (such as ASTM A106, API 5L, or DIN standards) are approved for delivery.

3. Material Properties and Chemical Composition

The chemical composition of seamless carbon steel determines its performance characteristics. A typical composition used in engine low-pressure pipes is shown below:

| Element | Content (%) | Function |

| Carbon (C) | 0.20–0.30 | Provides strength and hardness |

| Manganese (Mn) | 0.40–1.00 | Improves toughness and hardenability |

| Phosphorus (P) | ≤0.035 | Should be minimal to prevent brittleness |

| Sulfur (S) | ≤0.035 | Controls machinability but may reduce toughness |

The resulting material has a good balance of tensile strength, ductility, and corrosion resistance — ideal for low-pressure applications in engines and industrial fluid systems.

4. Key Advantages of Seamless Carbon Steel Engine Low Pressure Pipes

Seamless carbon steel pipes offer several advantages that make them indispensable in engine manufacturing and related sectors. Some of their major benefits include:

- High mechanical strength with excellent pressure-bearing capacity for low-pressure systems.

- Uniform microstructure due to seamless construction, ensuring consistent performance.

- Smooth internal surface reduces friction and enhances fluid flow efficiency.

- Superior resistance to leaks and mechanical stress compared to welded pipes.

- Easy to machine, bend, and fabricate for customized engine layouts.

- Long service life even in high-temperature, oil-rich, or corrosive environments.

5. Common Applications

Due to their strong mechanical and chemical stability, Seamless Carbon Steel Engine Low Pressure Pipes are widely used in multiple sectors. Below are typical areas where they are applied:

| Application Area | Specific Uses |

| Automotive Engines | Fuel lines, lubrication systems, coolant pipelines |

| Industrial Machinery | Hydraulic and pneumatic systems |

| Power Generation Equipment | Low-pressure steam and water pipelines |

| Oil and Gas Facilities | Oil transfer lines, low-pressure gas delivery |

6. Performance Comparison: Seamless vs. Welded Low Pressure Pipes

While both types are used for fluid conveyance, seamless pipes deliver better reliability and mechanical consistency. The following table summarizes the key differences:

| Property | Seamless Carbon Steel Pipe | Welded Steel Pipe |

| Manufacturing Method | Pierced and rolled from a solid billet | Formed and welded from steel plate |

| Pressure Resistance | High and uniform | Limited by weld seam strength |

| Internal Surface Smoothness | Excellent, ideal for fluid flow | Moderate; weld seam may obstruct flow |

| Leakage Probability | Very low | Possible along weld seams |

7. Maintenance and Handling Recommendations

Proper maintenance extends the operational life of Seamless Carbon Steel Engine Low Pressure Pipes and ensures reliable performance. Below are key guidelines for handling and upkeep:

- Regularly inspect for corrosion or scaling inside the pipes and clean with approved agents.

- Avoid over-tightening fittings to prevent stress cracks or deformation.

- Store in dry conditions to prevent rust, using protective end caps when possible.

- Apply suitable coatings or galvanization for outdoor or humid applications.

- Replace any pipes showing signs of pitting, dents, or uneven wall thickness.

8. Conclusion: Why Choose Seamless Carbon Steel Engine Low Pressure Pipes

Seamless Carbon Steel Engine Low Pressure Pipes combine strength, precision, and cost-effectiveness for diverse mechanical and industrial applications. Their ability to maintain stable flow under varying temperatures and pressures makes them indispensable in engine systems, hydraulic units, and low-pressure transport lines. When manufactured under strict standards and maintained properly, these pipes deliver outstanding performance, safety, and durability — making them a reliable choice for long-term, high-efficiency engineering operations.

English

English Español

Español русский

русский