In modern automobile engine systems, the oil pipeline, as an important part of the lubrication system, plays a key role in transporting oil and ensuring the normal operation of the engine. Especially in extreme working environments with high temperature, high pressure and frequent vibration, oil pipes made of traditional rubber or synthetic materials are prone to aging, expansion, leakage and other problems, affecting the stability and service life of the engine. In recent years, more and more high-performance vehicles have begun to use Low-Pressure PTFE Engine Oil Pipe to improve the reliability and durability of the system. So, under extreme working conditions, what advantages and reliability does this PTFE oil pipe show?

Excellent high temperature resistance is one of the most significant advantages of PTFE oil pipes. Polytetrafluoroethylene (PTFE) is an engineering plastic with excellent thermal stability, and its temperature resistance range can usually reach -60°C to +260°C. This means that even if the temperature in the engine compartment continues to rise, the PTFE oil pipe will not expand or soften like traditional rubber hoses, thereby effectively avoiding leakage problems caused by material deformation. This is especially important for turbocharged models, racing cars and vehicles that travel at high speeds for a long time.

PTFE oil pipes have excellent chemical corrosion resistance. Engine oil contains a variety of additives, and long-term contact may cause corrosion and degradation to ordinary rubber or plastic pipes. However, PTFE materials hardly react with any chemical substances, and they remain highly stable even in the face of common automotive fluids such as engine oil, coolant, and fuel, which greatly extends the service life of the oil pipe and reduces the frequency of maintenance.

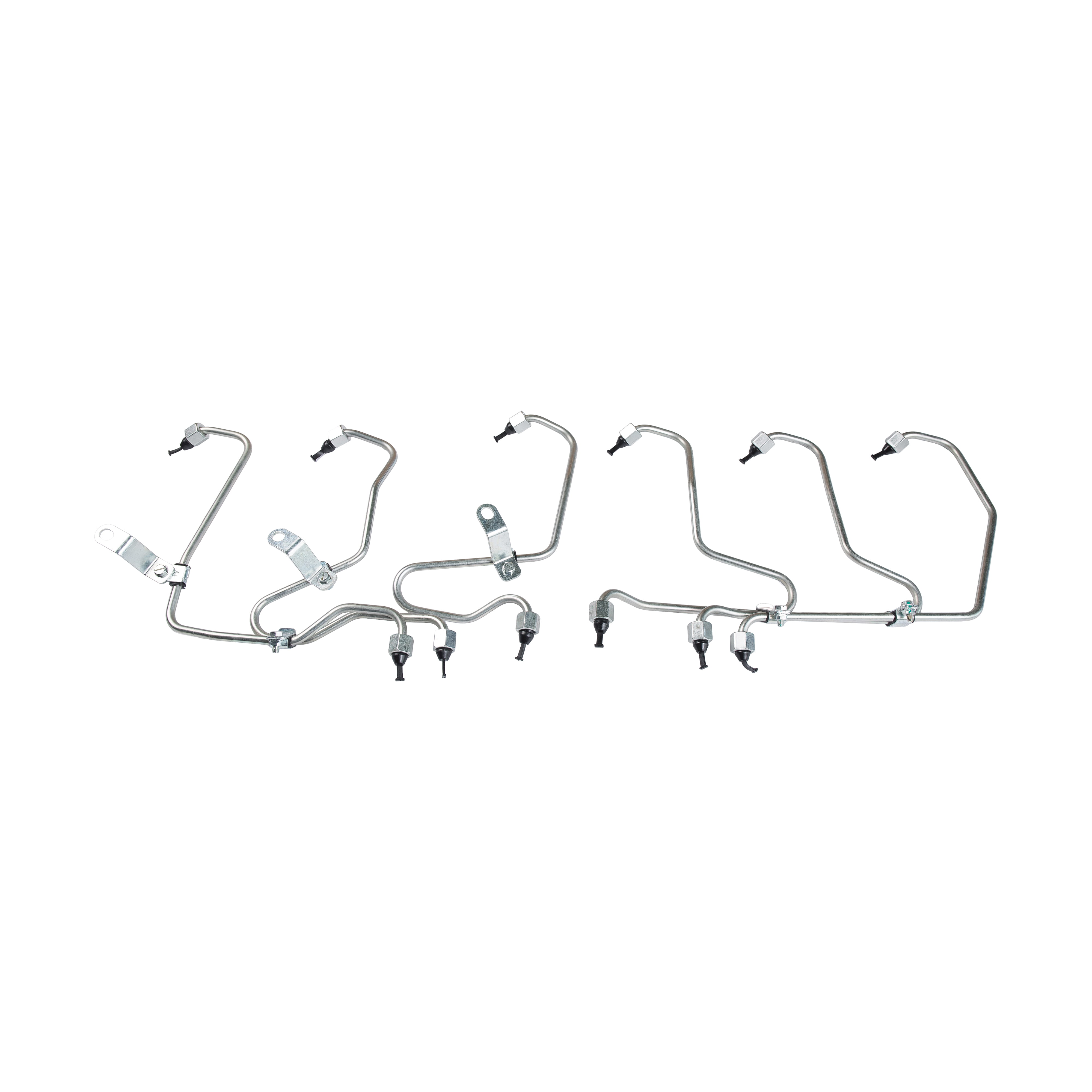

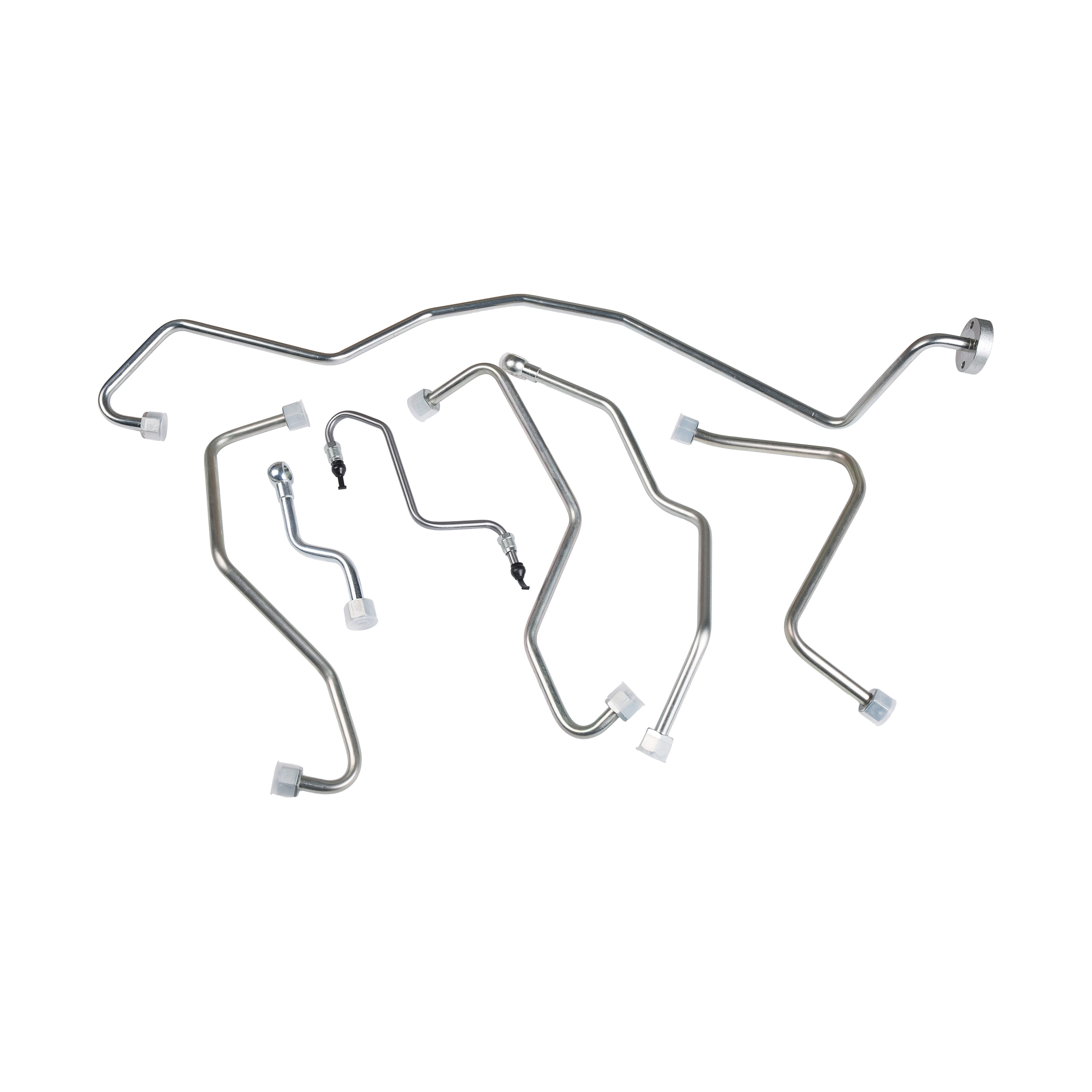

In addition, low-pressure PTFE engine oil pipes also perform well in terms of impermeability and sealing. Compared with the possibility of micro-permeation in traditional rubber pipes, PTFE has a dense structure and can effectively prevent trace leakage of engine oil, which not only improves the safety of the system, but also helps to meet increasingly stringent environmental regulations. At the same time, this type of oil pipe is usually wrapped with a stainless steel braided mesh on the outer layer, which further enhances the mechanical strength and burst resistance, ensuring stable operation under high-frequency vibration or pressure fluctuations.

The flexibility and installation adaptability of PTFE oil pipes are also very outstanding. Although PTFE is relatively hard, it can achieve flexible wiring without sacrificing strength through reasonable structural design (such as bellows or bendable joints), and is suitable for various complex layouts of engine compartments. This makes it more advantageous in application scenarios with high requirements for space layout, such as modified vehicles, off-road vehicles, and heavy trucks.

From the perspective of long-term use cost and maintenance, although the initial investment of PTFE oil pipes is higher than that of traditional rubber pipes, due to their long life, low failure rate, and low replacement frequency, the overall cost performance is higher. Especially in commercial transport vehicles or competitive racing cars in harsh environments, the use of PTFE oil pipes can significantly reduce the risk of downtime maintenance caused by oil circuit failures and improve operational efficiency.

Low-pressure PTFE engine oil pipes have excellent high temperature resistance, corrosion resistance, sealing, structural strength and good adaptability, and show reliability far exceeding traditional materials in extreme working environments. With the continuous improvement of the automotive industry's requirements for performance, safety and environmental protection, PTFE oil pipes are gradually becoming an ideal choice for high-end and professional vehicle lubrication systems.

English

English Español

Español русский

русский