Polytetrafluoroethylene (PTFE) pipes are widely used in industrial, chemical, food, pharmaceutical, and electronic applications due to their excellent chemical resistance, high temperature tolerance, and non-stick properties. For engineers, contractors, and maintenance teams, one common question is whether PTFE pipe series are easy to install. The answer is generally yes, but understanding the properties, installation techniques, and best practices is essential to ensure efficiency and reliability.

1. Material Properties That Aid Installation

PTFE pipes are lightweight compared to metal or other rigid piping systems, which makes them easier to handle, transport, and position during installation. Their flexibility allows them to accommodate bends and turns without extensive fittings, reducing the need for elbow joints in certain applications. Additionally, PTFE’s chemical inertness and smooth inner surface minimize the risk of contamination during installation, which is especially important in food, pharmaceutical, and chemical industries.

2. Connection Methods

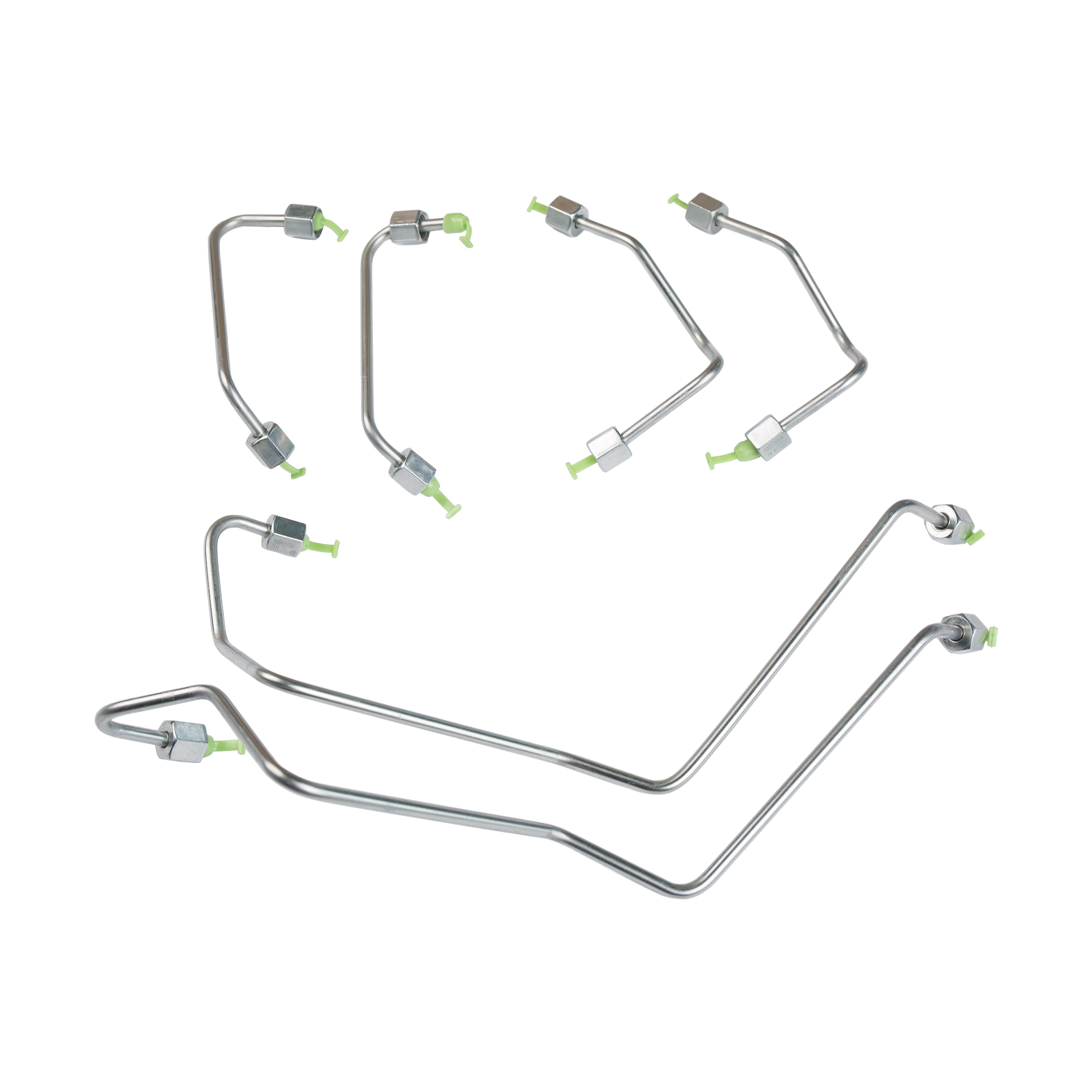

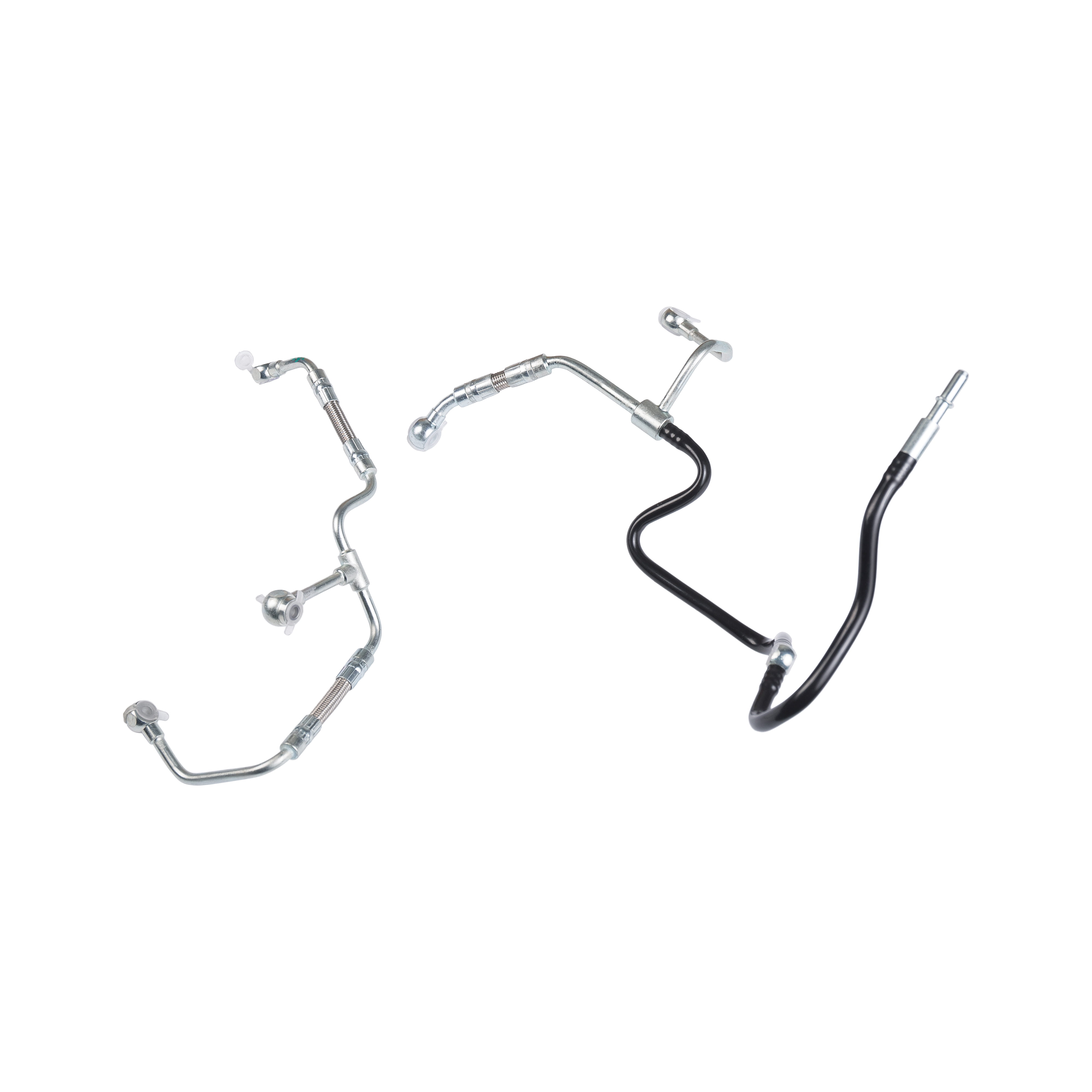

PTFE pipes can be installed using several common connection methods, depending on the application and pipe size:

Flanged connections: Provide a strong, leak-free seal for high-pressure or large-diameter applications.

Compression fittings: Allow easy joining of PTFE pipes without the need for welding or complex tools.

Threaded adapters: Simplify installation for smaller-diameter pipes in low-pressure systems.

These connection options make PTFE pipes versatile and relatively easy to integrate into existing piping systems. Unlike metal pipes, which may require welding or heavy-duty support, PTFE pipes can be installed using standard tools and fittings.

3. Installation Steps

The basic steps for installing PTFE pipes are straightforward:

Measurement and cutting: PTFE pipes can be cut to the required length using a sharp pipe cutter or fine-tooth saw. Clean, straight cuts ensure proper fitting.

Cleaning the ends: Remove any debris or burrs from cut ends to prevent leaks or obstruction.

Fitting connections: Use the appropriate fittings—flanges, compression joints, or threaded adapters—to connect sections. Ensure all seals and gaskets are properly positioned.

Testing: After installation, check for leaks and ensure that the system maintains the required pressure and flow rate.

Following these steps makes the installation process manageable even for personnel with moderate technical experience.

4. Advantages Over Traditional Materials

Compared to metal, PVC, or rubber piping, PTFE pipes offer several advantages in ease of installation:

Lightweight: Reduces labor effort and handling equipment requirements.

Flexibility: Minimizes the number of fittings needed for bends and curves.

Corrosion-free: No special protective coatings or treatments are needed.

Non-stick surface: Prevents fouling during installation, making pipe joining cleaner and faster.

These properties make PTFE piping systems ideal for complex layouts, retrofits, or areas with limited access.

5. Precautions for Proper Installation

While PTFE pipes are relatively easy to install, certain precautions ensure long-term reliability:

Avoid excessive bending, which can cause kinks or reduce flow capacity.

Ensure that all fittings are compatible with PTFE material and rated for the system’s pressure and temperature.

Allow for thermal expansion, as PTFE pipes can expand or contract with temperature fluctuations.

Avoid sharp or abrasive tools that could scratch or damage the pipe surface.

By following these guidelines, installation becomes straightforward while maintaining the integrity and longevity of the system.

6. Applications and Practical Considerations

PTFE pipe series are suitable for a wide range of applications: chemical processing lines, pharmaceutical fluid transfer, food-grade piping, electronic manufacturing, and laboratory systems. Their easy installation and adaptability make them a preferred choice in industries where downtime must be minimized and cleanliness is critical. Small-diameter PTFE tubing can be installed quickly for laboratory or instrumentation applications, while larger-diameter industrial piping can be efficiently fitted using flanges or compression joints.

Conclusion

The PTFE pipe series is generally easy to install due to its lightweight, flexible nature and versatile connection options. Compared to traditional metal or rigid piping, PTFE requires less effort to handle and fit, making it suitable for both small-scale and industrial installations. By following proper installation procedures—cutting accurately, using compatible fittings, and accounting for thermal expansion—engineers and technicians can achieve reliable, leak-free piping systems. Its combination of chemical resistance, durability, and ease of installation makes PTFE piping a practical and efficient choice for modern industrial and laboratory applications.

English

English Español

Español русский

русский