A seamless carbon steel engine low pressure pipe is a type of tubular component used in automotive, industrial, and mechanical applications to transport fluids such as coolant, fuel, or lubricants at relatively low pressures. Unlike welded or fabricated pipes, seamless pipes are manufactured without joints or welds, providing superior strength, uniformity, and reliability. They are widely used in engine systems where consistent performance and safety are critical.

1. Definition and Composition

Seamless carbon steel pipes are made from high-quality carbon steel billets. The steel is heated and then pierced or drawn to form a tube, eliminating the need for welding. This produces a smooth, uniform structure with no seams or weak points, which is particularly important in applications involving vibrations, thermal expansion, or pressure fluctuations.

The term “low pressure” refers to the operational pressure for which the pipe is designed. In engine systems, low-pressure pipes generally handle fluids at pressures significantly below high-pressure fuel lines or hydraulic systems. This makes them suitable for coolant circuits, air intake systems, and oil return lines.

2. Advantages of Seamless Carbon Steel Pipes

Seamless carbon steel pipes offer several benefits compared to welded or fabricated alternatives:

- Strength and Durability: The absence of a welded seam reduces the risk of failure under stress, pressure, or thermal cycling.

- Corrosion Resistance: Properly coated or treated carbon steel can resist rust and corrosion, prolonging the pipe’s service life.

- Uniform Wall Thickness: Seamless construction ensures consistent wall thickness, which is critical for maintaining structural integrity and predictable fluid flow.

- Thermal Stability: Seamless pipes can withstand temperature fluctuations without compromising strength, making them ideal for engine environments.

- Precision Fit: They are manufactured to strict dimensional tolerances, ensuring compatibility with engine components and reducing leakage risks.

3. Manufacturing Process

The production of seamless carbon steel pipes generally involves the following steps:

- Billet Preparation: High-quality carbon steel billets are selected and heated to a high temperature to increase malleability.

- Piercing and Extrusion: A solid billet is pierced through the center to create a hollow tube. It may then be rolled or stretched to achieve the desired diameter and wall thickness.

- Heat Treatment: Pipes may undergo normalization or annealing to relieve internal stresses and improve toughness.

- Cutting and Finishing: Pipes are cut to specified lengths, and the ends are beveled or threaded if required.

- Surface Treatment: Pipes may be coated, galvanized, or painted to enhance corrosion resistance and surface quality.

This seamless process ensures a homogeneous material structure and eliminates weld-related weaknesses.

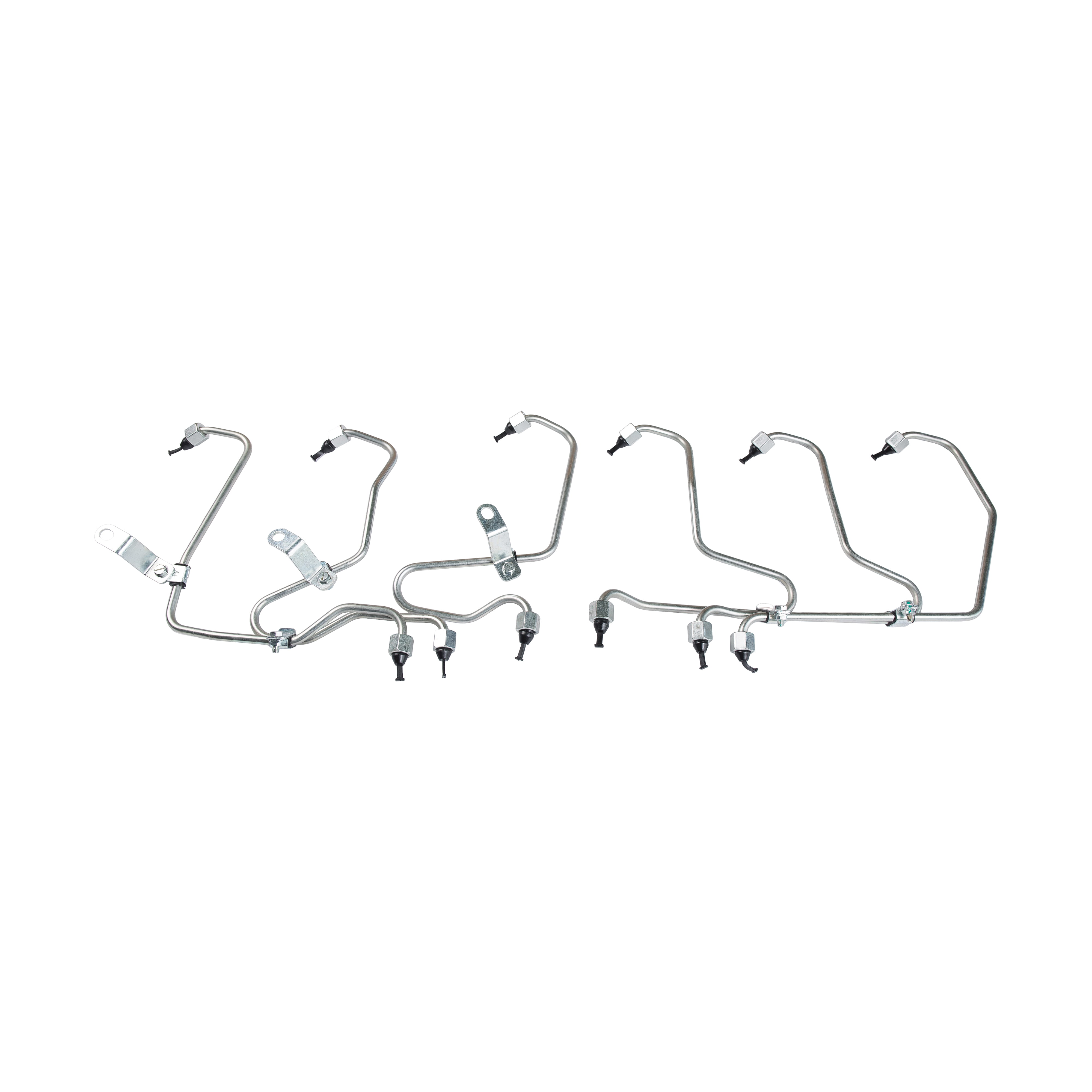

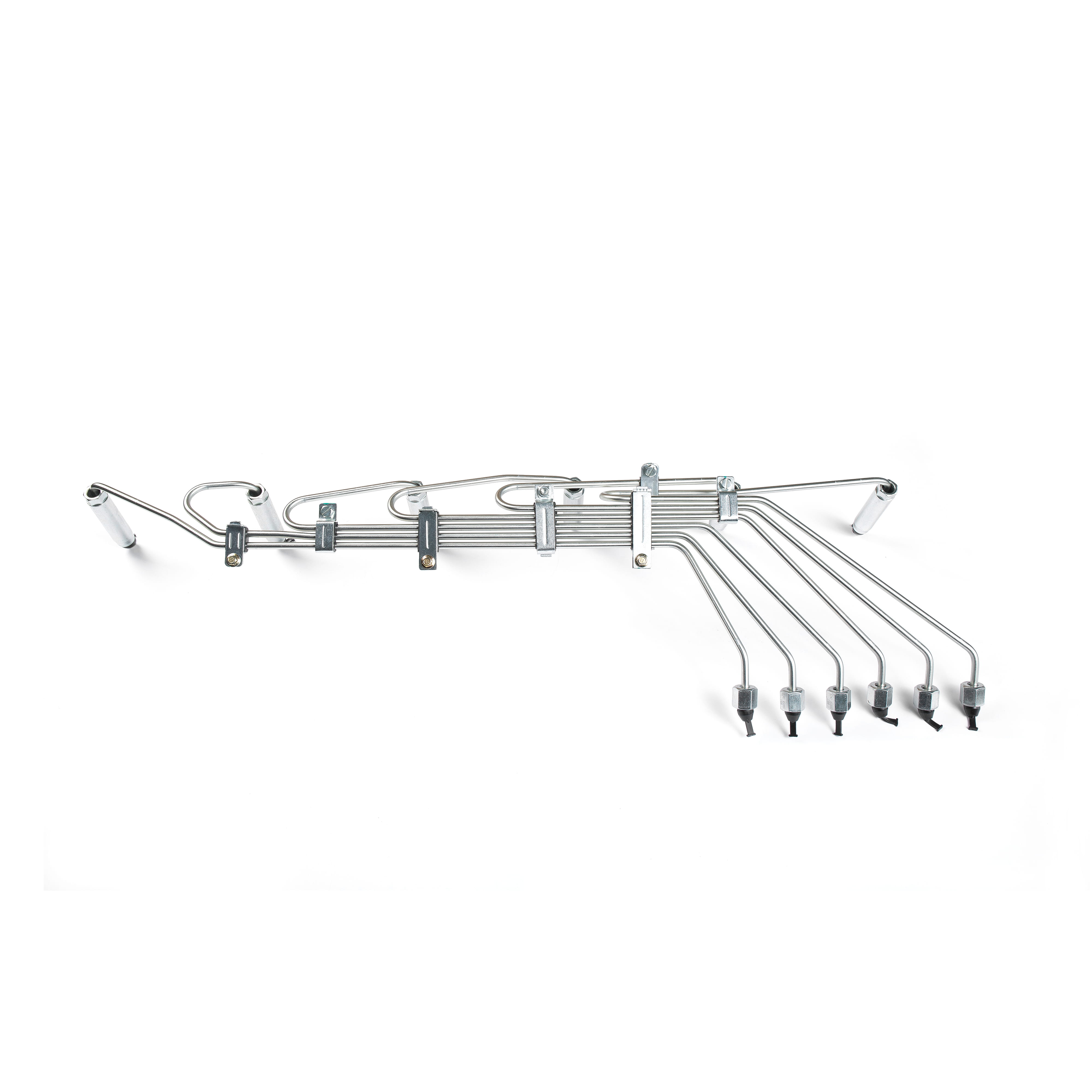

4. Applications in Engine Systems

Seamless carbon steel engine low pressure pipes are commonly used in:

- Coolant Circuits: Carrying engine coolant between radiators, pumps, and engine blocks.

- Oil Lines: Returning lubricating oil from components to oil pans or filters.

- Air Intake and Vacuum Systems: Conducting air or low-pressure gases within engine compartments.

- Fuel Systems: For low-pressure fuel delivery in carbureted engines or fuel injection systems.

In these applications, the combination of strength, durability, and dimensional accuracy ensures reliable operation under varying thermal and mechanical loads.

5. Standards and Specifications

Seamless carbon steel pipes are manufactured according to international standards such as ASTM A53, ASTM A106, EN 10216, and others. These standards define mechanical properties, dimensional tolerances, chemical composition, and testing requirements.

Key specifications include:

- Outer diameter and wall thickness: Determined by engine design and fluid flow requirements.

- Material grade: Carbon content and alloying elements influence strength and corrosion resistance.

- Pressure rating: Pipes are rated for specific low-pressure ranges, ensuring safe operation.

Meeting these standards guarantees consistency, reliability, and compatibility with global engine systems.

6. Advantages Over Other Pipe Types

Compared to welded or composite pipes, seamless carbon steel pipes provide:

- Higher reliability under thermal cycling and vibration.

- Lower risk of leaks or ruptures due to uniform structure.

- Longer service life in harsh environments.

These features make seamless carbon steel the preferred choice for engine low-pressure applications, where safety, durability, and precision are critical.

Conclusion

A seamless carbon steel engine low pressure pipe is a high-quality tubular component designed to transport fluids such as coolant, oil, or air in engine systems at low pressures. Its seamless construction, uniform wall thickness, and robust material properties provide superior strength, reliability, and durability compared to welded alternatives.

Manufactured through piercing, extrusion, heat treatment, and finishing processes, these pipes meet international standards and are widely used in automotive, industrial, and mechanical applications. With advantages such as corrosion resistance, thermal stability, and precise dimensions, seamless carbon steel pipes ensure long-term, safe operation in engine systems and other low-pressure fluid applications.

English

English Español

Español русский

русский