Introduction to Low-Pressure Oil Pipes

Low-pressure oil pipes are essential components in automotive and industrial hydraulic systems. They transport lubricants and hydraulic fluids under relatively low pressures, ensuring smooth operation of engines, machinery, and other mechanical systems. Choosing the correct material is crucial for performance, safety, and longevity.

Common Materials for Low-Pressure Oil Pipes

Low-pressure oil pipes are manufactured from a variety of materials, including rubber, PVC, reinforced nylon, and metal. Each material offers distinct advantages and disadvantages, influencing durability, flexibility, chemical resistance, and installation requirements.

Rubber Oil Pipes

Rubber is the most widely used material for low-pressure oil pipes due to its flexibility and ease of installation. Rubber pipes can withstand moderate heat and pressure, making them suitable for automotive fuel lines, hydraulic systems, and general lubrication applications. However, rubber may degrade over time when exposed to certain oils, UV light, or extreme temperatures.

PVC Oil Pipes

PVC pipes are lightweight and resistant to corrosion and chemicals. They are ideal for applications requiring clear visibility of the fluid or where flexibility is needed without kinking. PVC is less heat-resistant than rubber and may become brittle under prolonged exposure to high temperatures.

Reinforced Nylon Pipes

Reinforced nylon oil pipes are highly durable and resistant to abrasion, pressure fluctuations, and chemical degradation. They are commonly used in industrial equipment and performance automotive systems. These pipes offer excellent strength but may be less flexible than rubber or PVC.

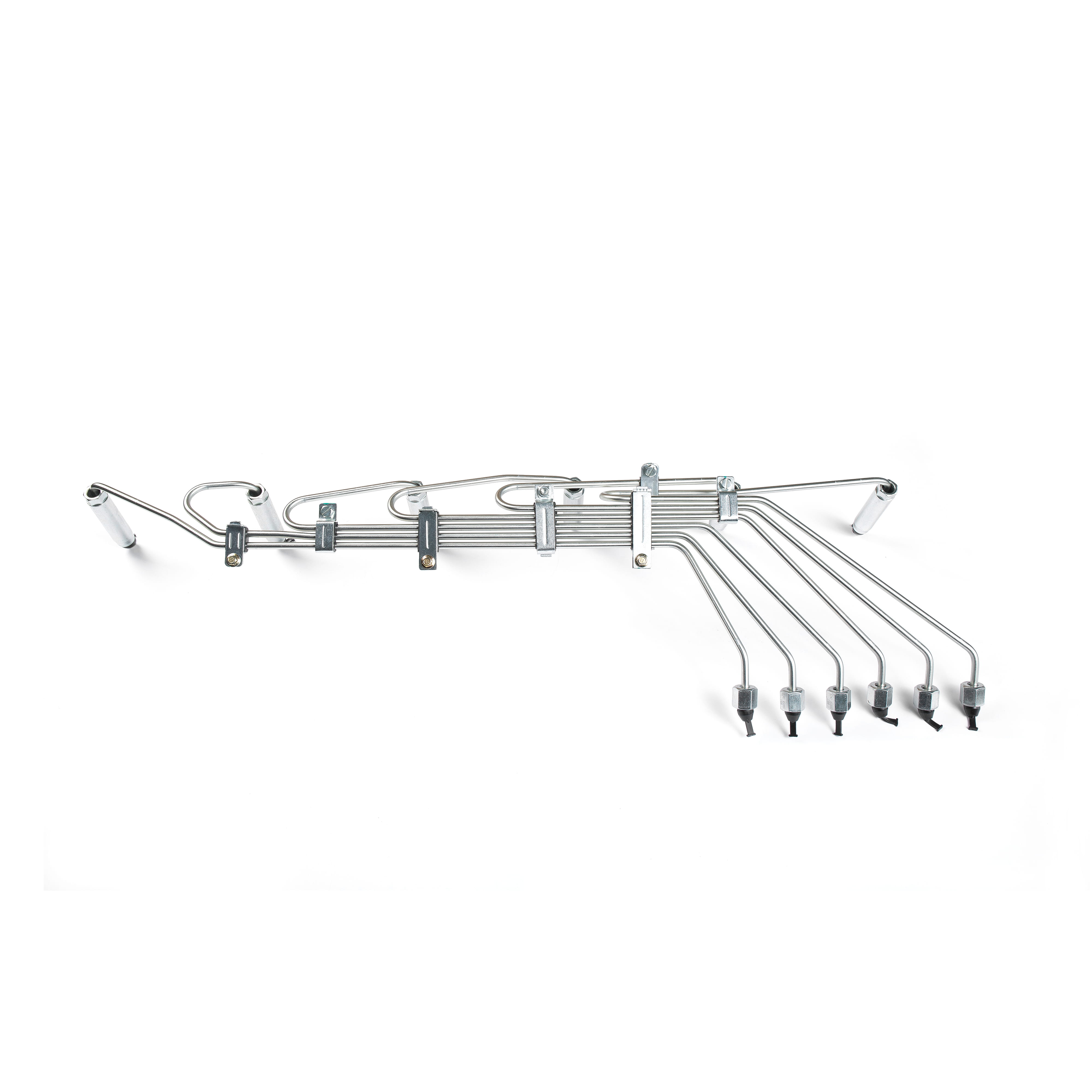

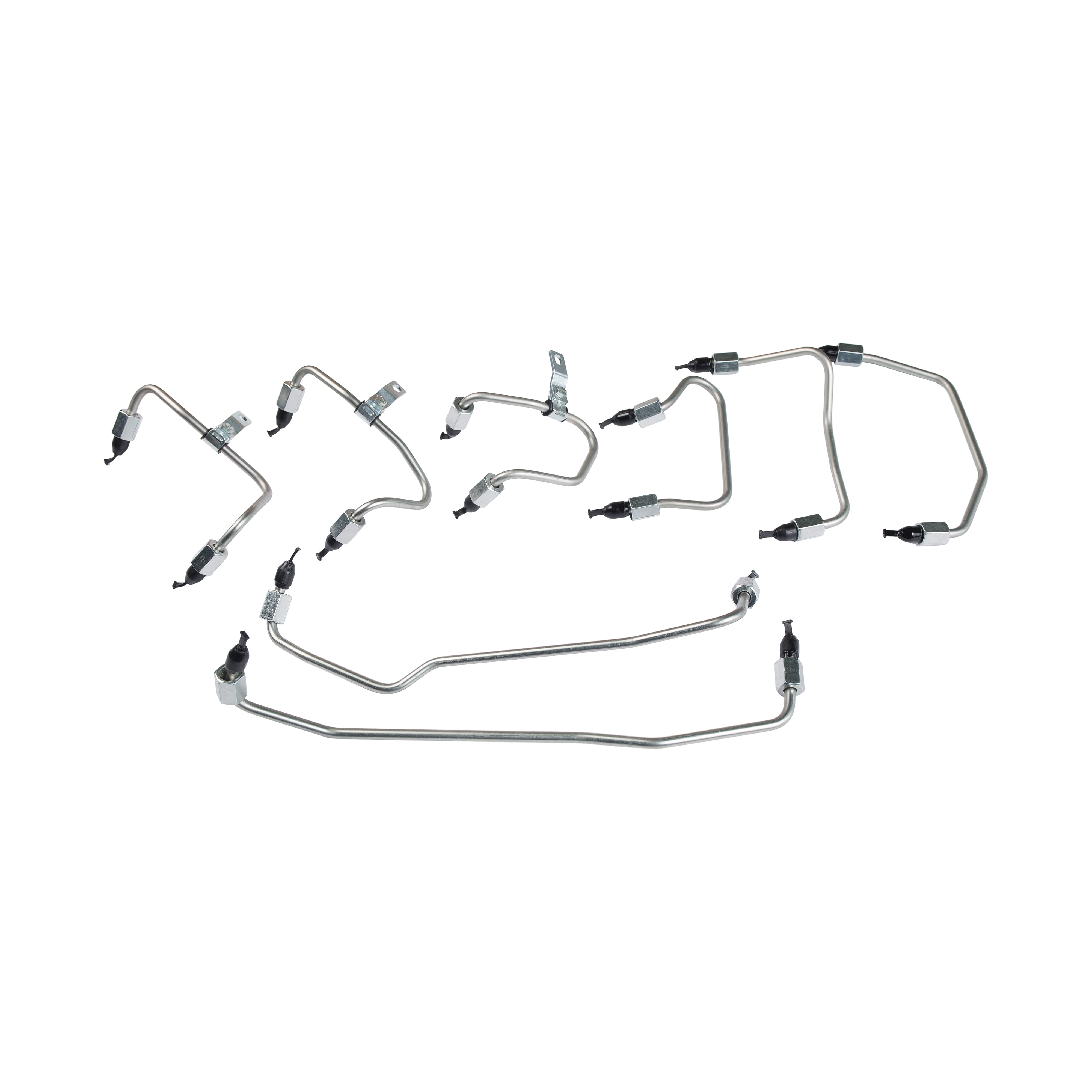

Metal Pipes

Metal pipes, such as stainless steel or aluminum, provide maximum durability and resistance to high temperatures and physical damage. They are suitable for critical applications requiring long-term reliability. Metal pipes are rigid, heavier, and require precise fittings for installation.

Performance Comparison of Different Materials

The choice of material affects several key performance metrics, including flexibility, chemical resistance, temperature tolerance, and lifespan. Understanding these differences helps users select the most suitable oil pipe for their application.

- Rubber: High flexibility, moderate durability, good chemical resistance, moderate temperature tolerance.

- PVC: Lightweight, corrosion-resistant, moderate flexibility, limited heat tolerance.

- Reinforced Nylon: High strength, excellent chemical resistance, good pressure tolerance, lower flexibility.

- Metal: Maximum durability and heat resistance, rigid, requires secure fittings, long lifespan.

Comparison Table of Low-Pressure Oil Pipe Materials

| Material | Flexibility | Chemical Resistance | Temperature Tolerance | Lifespan |

| Rubber | High | Moderate | Moderate | 3–5 years |

| PVC | Moderate | Good | Low–Moderate | 2–4 years |

| Reinforced Nylon | Low–Moderate | Excellent | High | 5–8 years |

| Metal | Low (Rigid) | Excellent | Very High | 10+ years |

Applications Based on Material Selection

Different materials are suited for specific applications depending on operational conditions. Matching material properties with system requirements ensures efficiency, safety, and longevity.

Automotive Systems

Rubber and PVC oil pipes are commonly used in automotive fuel lines, oil circulation, and low-pressure hydraulic systems. Their flexibility and moderate durability allow for easy routing within engine compartments and machinery.

Industrial Equipment

Reinforced nylon and metal pipes are preferred for industrial hydraulic systems, machinery lubrication, and high-temperature environments. They offer high durability and resistance to chemical degradation.

Specialized Applications

Critical systems requiring long-term reliability, such as aircraft or marine equipment, often use metal pipes due to their superior lifespan, resistance to environmental factors, and minimal maintenance requirements.

Maintenance Tips for Low-Pressure Oil Pipes

Proper maintenance extends the life of oil pipes regardless of material. Regular inspection, leak detection, and cleaning prevent failures and ensure efficient operation.

- Inspect pipes for cracks, bulges, or discoloration.

- Check connections and fittings for tightness.

- Clean pipes periodically to remove sludge or debris.

- Replace worn or damaged pipes immediately to prevent leaks or system failure.

Conclusion: Choosing the Right Material

Selecting the appropriate low-pressure oil pipe material depends on flexibility, chemical resistance, temperature tolerance, and expected lifespan. Rubber and PVC are ideal for general applications requiring flexibility, while reinforced nylon and metal pipes are suitable for demanding industrial or high-temperature conditions. Understanding these differences ensures safe, efficient, and durable hydraulic and lubrication systems.

English

English Español

Español русский

русский