Introduction to Low-Pressure Oil Pipes

Low-pressure oil pipes are critical components in automotive, industrial, and hydraulic systems. Unlike high-pressure pipes, they are designed to transport oil at lower pressures, typically under 10 bar, ensuring safe and efficient fluid flow. These pipes play a significant role in maintaining engine performance, reducing leaks, and preventing damage to sensitive components. Understanding their characteristics and applications is essential for engineers, mechanics, and industrial operators.

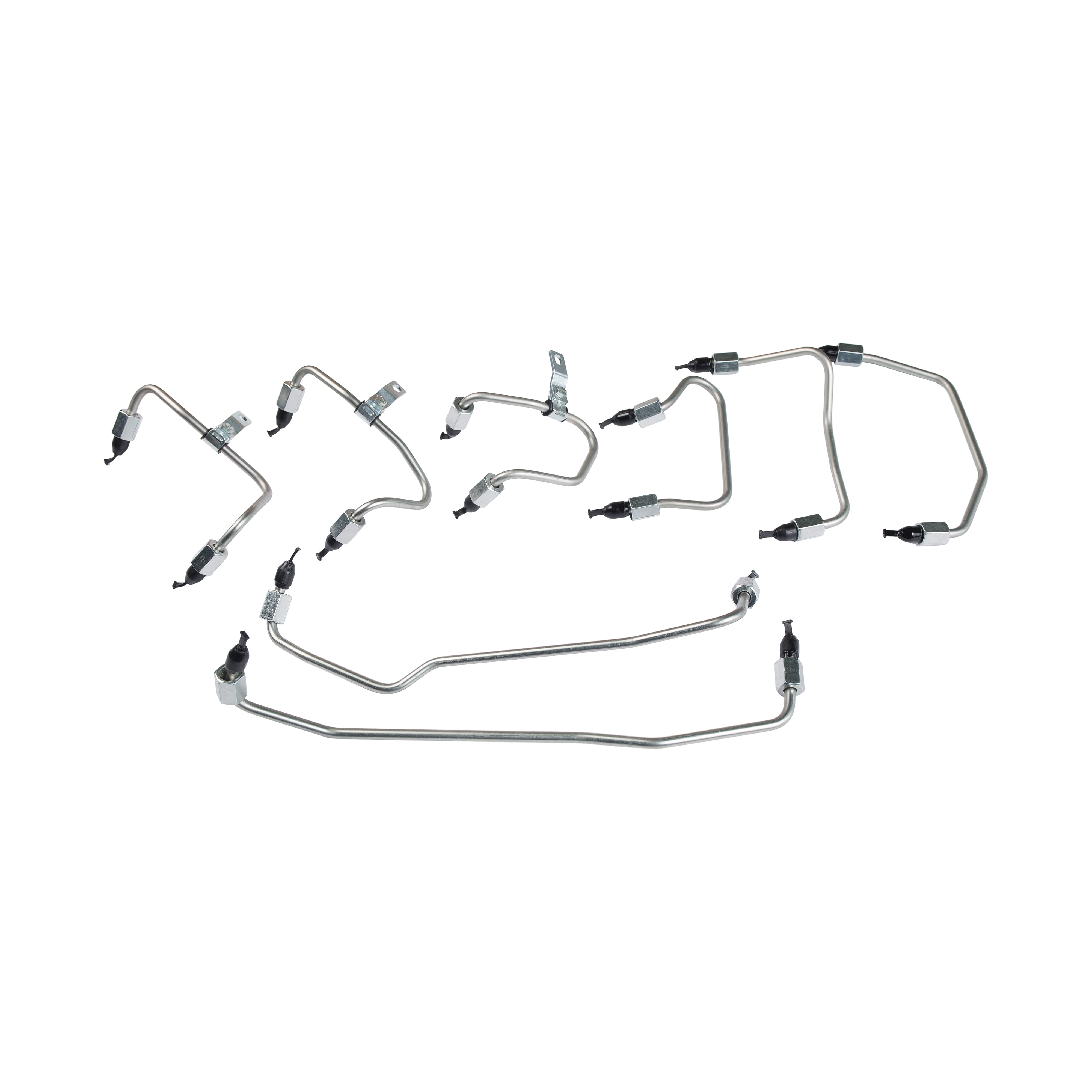

Key Characteristics of Low-Pressure Oil Pipes

Material Composition

Low-pressure oil pipes are commonly made from materials such as rubber, thermoplastic, or flexible metal. Rubber hoses are widely used due to their flexibility, resistance to vibration, and cost-effectiveness. Thermoplastic pipes offer higher chemical resistance and longer lifespan. Some applications use reinforced flexible metal pipes to withstand moderate pressure and prevent deformation.

Pressure and Temperature Tolerance

These pipes are designed to handle operating pressures between 0.5 to 10 bar. They are capable of withstanding temperatures from -40°C to 120°C depending on the material. Rubber hoses often include synthetic reinforcements such as nylon or polyester fibers to enhance pressure resistance while maintaining flexibility.

Flexibility and Durability

One of the major advantages of low-pressure oil pipes is their flexibility. This allows for easy installation in tight spaces within engines or machinery. Additionally, durability is achieved through reinforced layers and protective coatings that resist abrasion, ozone, and oil degradation over time.

Applications of Low-Pressure Oil Pipes

Automotive Systems

In vehicles, low-pressure oil pipes are widely used for lubricating systems, oil return lines, and transmission fluid circuits. They ensure consistent oil flow to engine components such as bearings, camshafts, and turbochargers. Proper installation and maintenance prevent leaks that could cause engine wear or failures.

Industrial Machinery

Industrial machines often rely on low-pressure oil pipes for hydraulic lubrication, coolant circulation, and oil return systems. Examples include conveyor systems, compressors, and turbines. These pipes help maintain system efficiency, reduce friction, and prolong equipment life by ensuring consistent oil delivery.

Agricultural Equipment

Tractors, harvesters, and other agricultural machinery frequently use low-pressure oil pipes for engine lubrication and hydraulic operations. Flexible hoses allow these systems to withstand vibration, movement, and varying temperatures, ensuring reliable performance under harsh conditions.

Design Considerations for Low-Pressure Oil Pipes

Size and Diameter Selection

Choosing the correct diameter is essential to maintain oil flow and prevent pressure drops. Engineers typically select pipes with an inner diameter that matches the system's flow requirements while considering space constraints for routing.

Compatibility with Fluids

Low-pressure oil pipes must be compatible with the type of oil used, including synthetic, mineral, or vegetable-based oils. Material selection ensures chemical resistance and prevents pipe degradation, swelling, or cracking during operation.

Installation and Maintenance

Proper installation involves securing the pipes to prevent vibration, kinking, or abrasion against metal parts. Regular inspection and maintenance, including checking for leaks or soft spots, help prolong the life of low-pressure oil pipes and maintain system efficiency.

Comparison of Common Low-Pressure Oil Pipe Materials

| Material | Pressure Range | Temperature Range | Key Advantages |

| Rubber | 0.5–10 bar | -40°C to 100°C | Flexible, cost-effective, vibration resistant |

| Thermoplastic | 1–10 bar | -40°C to 120°C | Chemical resistant, durable, long lifespan |

| Reinforced Metal | 2–10 bar | -20°C to 150°C | Moderate pressure resistance, prevents deformation |

Common Problems and Troubleshooting

Leakage Issues

Leakage is the most common issue with low-pressure oil pipes, often caused by improper installation, wear, or incompatible materials. Inspect connections and replace damaged sections promptly to prevent system failures.

Kinking and Bending

Kinks reduce oil flow and can lead to premature pipe failure. Pipes should be routed with gradual bends and secured to avoid sharp angles.

Material Degradation

Exposure to high temperatures, chemical reactions, or prolonged vibration can degrade pipe material. Regular inspections help identify soft spots, cracks, or swelling before serious problems occur.

Conclusion

Low-pressure oil pipes are vital for the safe and efficient operation of automotive, industrial, and agricultural systems. Understanding their characteristics, selecting the appropriate material, and ensuring proper installation and maintenance can significantly enhance system reliability. By considering pressure tolerance, temperature range, flexibility, and fluid compatibility, engineers and operators can optimize performance while minimizing downtime and maintenance costs.

English

English Español

Español русский

русский