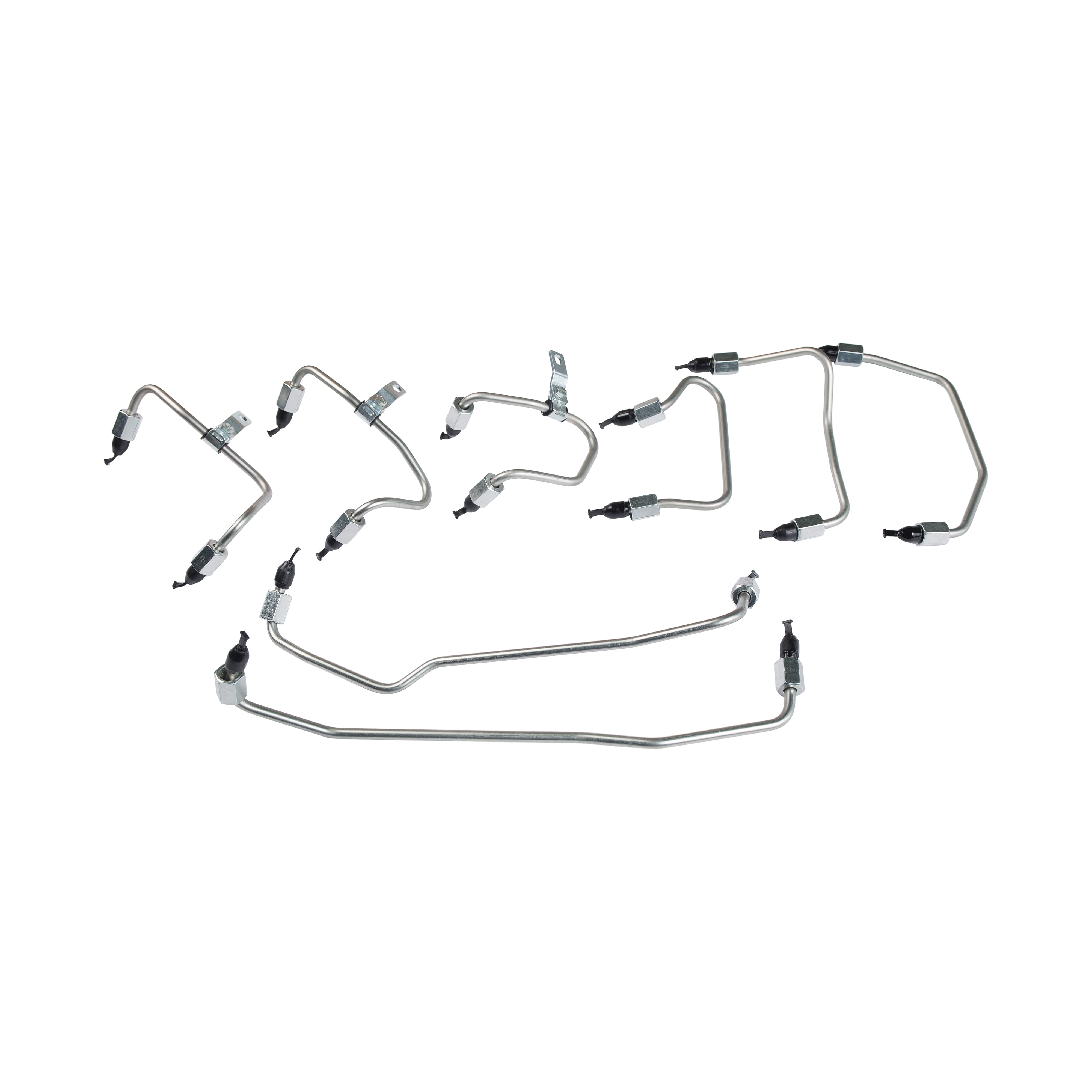

A Low-Pressure PTFE Engine Oil Pipe is a specialized fluid conveyance component used in internal combustion engines to transport engine oil between various parts of the lubrication system under low-pressure conditions. Unlike high-pressure oil lines that handle pressurized oil from the oil pump to critical engine components, low-pressure PTFE oil pipes are typically used in return lines, ventilation systems, or auxiliary oil circuits where pressure is minimal. Constructed with Polytetrafluoroethylene (PTFE) as the inner liner, these hoses offer superior chemical resistance, thermal stability, and durability compared to traditional rubber or synthetic hoses.

Below are the key aspects that define and explain the low-pressure PTFE engine oil pipe:

1. Material Composition: PTFE Inner Liner with Reinforcement

The core of a low-pressure PTFE engine oil pipe is a seamless tube made of PTFE, a high-performance fluoropolymer known for its exceptional resistance to heat, oil, and chemicals. This inner liner is often reinforced with a braided layer of stainless steel or synthetic fibers to enhance flexibility and prevent kinking, even though the operating pressure is low. The outer layer may be made of protective thermoplastic or heat-resistant coating to guard against abrasion and environmental damage.

2. Designed for Low-Pressure Applications

As the name suggests, these pipes are engineered for low-pressure environments, typically handling pressures below 50 psi (3.5 bar). They are commonly used in:

Oil return lines from cylinder heads or turbochargers

Crankcase ventilation (PCV) systems

Oil breather lines

Auxiliary oil cooler bypass circuits

They are not intended for high-pressure zones such as main oil galleries or oil pump outlets.

3. Excellent Resistance to Engine Oil and Additives

Engine oils contain detergents, dispersants, and other additives that can degrade rubber hoses over time. PTFE, however, is chemically inert and highly resistant to virtually all automotive fluids, including conventional, synthetic, and high-temperature oils. This ensures long-term reliability and prevents internal swelling, cracking, or deterioration.

4. High Temperature Tolerance

PTFE can withstand continuous operating temperatures from -70°C to +260°C (-94°F to +500°F), making it ideal for engine bays where heat from exhaust manifolds, turbochargers, and cooling systems can exceed 150°C. Traditional rubber hoses may harden, crack, or melt under such conditions, but PTFE maintains its structural integrity.

5. Superior Longevity and Durability

Due to its resistance to heat, oil, and oxidation, a PTFE oil pipe lasts significantly longer than rubber alternatives. It does not degrade from ozone exposure or UV radiation, and it resists abrasion when properly protected. This reduces maintenance frequency and the risk of unexpected oil leaks.

6. Flexibility and Ease of Installation

Despite its robust construction, low-pressure PTFE pipe remains flexible and can be bent to fit tight engine compartments. Pre-formed or cut-to-length options are available, and they can be fitted with aluminum, stainless steel, or brass fittings using proper crimping or attachment methods.

7. Leak Prevention and Sealing Performance

The smooth inner surface of PTFE reduces flow resistance and minimizes the risk of oil residue buildup. When paired with high-quality fittings, these pipes provide a reliable, leak-free connection, critical for maintaining engine cleanliness and performance.

8. Common Applications in Performance and Industrial Engines

Low-pressure PTFE oil pipes are widely used in:

High-performance and racing engines

Turbocharged and supercharged vehicles

Heavy-duty trucks and industrial machinery

Marine and aviation engines

Their reliability makes them a preferred upgrade over OEM rubber hoses.

A low-pressure PTFE engine oil pipe is a high-performance, durable solution for non-pressurized oil transfer systems in modern engines. Combining the chemical and thermal resistance of PTFE with mechanical strength and flexibility, it offers a significant improvement over traditional materials. Whether used for reliability in daily drivers or performance in racing applications, PTFE oil pipes enhance engine safety, reduce maintenance, and support long-term operational efficiency.

English

English Español

Español русский

русский