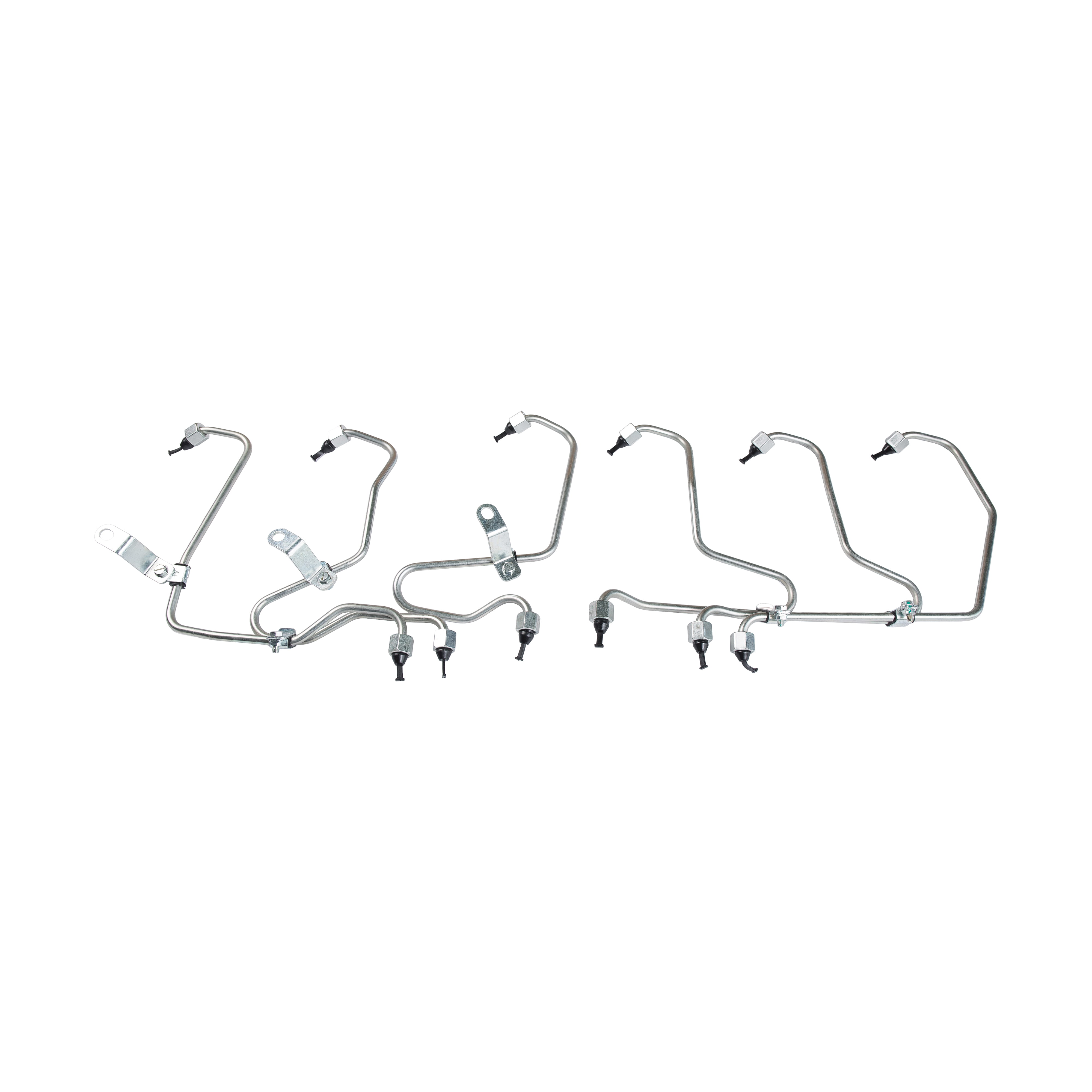

A Seamless Carbon Steel Engine Low Pressure Pipe is a type of precision metal tubing designed for use in engine and mechanical systems where low to moderate fluid or gas pressure is involved. Made from carbon steel without any welded seams, this pipe offers high strength, uniform structure, and reliable performance in demanding environments. It is widely used in automotive, industrial machinery, power generation, and hydraulic systems. Below is a detailed, point-by-point explanation of what this pipe is, including its composition, manufacturing process, properties, applications, and advantages.

1. Definition and Basic Structure

Seamless: Means the pipe is formed as a single, continuous piece without any welded joints or seams. This eliminates weak points along the length of the tube, enhancing structural integrity.

Carbon Steel: Refers to an iron-carbon alloy, typically containing 0.1% to 0.5% carbon. Higher carbon content increases strength and hardness. Common grades include ASTM A106, API 5L, and ASTM A53.

Low Pressure: Indicates the pipe is designed to handle pressures typically below 300 psi (20 bar), suitable for non-critical fluid transfer such as coolant, oil return lines, air intake, or fuel delivery in engines.

Used primarily in engine compartments for routing fluids or gases between components.

2. Manufacturing Process

Seamless pipes are produced using advanced thermal and mechanical techniques:

Hot Rolling:

A solid billet of carbon steel is heated above 1,200°C and pierced through a mandrel to form a hollow tube.

Then rolled and stretched to achieve the desired diameter and wall thickness.

Best for larger diameters and thicker walls.

Cold Drawing:

A hot-rolled tube is further processed at room temperature through dies and mandrels.

Improves dimensional accuracy, surface finish, and mechanical strength.

Commonly used for precision engine pipes.

No Welding Involved: Unlike ERW (Electric Resistance Welded) pipes, seamless tubes avoid potential defects at the weld line, making them more reliable under stress.

3. Key Material Properties

High Strength-to-Weight Ratio: Carbon steel provides excellent mechanical strength while remaining relatively lightweight.

Uniform Grain Structure: The seamless process creates consistent metallurgical properties around the entire circumference.

Good Thermal Conductivity: Helps dissipate heat in engine environments.

Ductility and Toughness: Can withstand vibration and minor impacts without cracking—critical in engine bays.

Machinability and Weldability: Can be cut, bent, threaded, or welded to fit complex engine layouts.

4. Common Specifications and Standards

These pipes adhere to international standards to ensure quality and compatibility:

ASTM A179: Standard specification for seamless cold-drawn low-carbon steel heat exchanger and condenser tubes.

ASTM A106: For high-temperature service, often used in engine exhaust or heating systems.

API 5L: Common in oil and gas applications, also used in heavy-duty engine systems.

DIN 2391 / EN 10305: European standards for precision seamless steel tubes used in hydraulic and engine applications.

Available in various outer diameters (OD), wall thicknesses, and lengths, customizable for OEM or aftermarket use.

5. Typical Applications

Seamless carbon steel low pressure pipes are used in:

Automotive Engines: For oil return lines, vacuum lines, coolant transfer, and turbocharger interconnects.

Industrial Engines: In generators, compressors, and pumps where reliable fluid transport is essential.

Hydraulic Systems: Low-pressure hydraulic circuits in machinery.

Fuel Systems: Non-critical fuel delivery lines (not for high-pressure direct injection).

Pneumatic Systems: Air transfer lines in engine control systems.

Marine and Agricultural Equipment: Where durability and corrosion resistance (with coating) are required.

Note: For high-pressure fuel or brake lines, higher-grade or stainless steel pipes may be preferred.

6. Advantages Over Other Pipe Types

vs. Welded Pipes: Seamless pipes have no weak seam, reducing the risk of leakage or failure under pressure or vibration.

vs. Plastic Hoses: More heat-resistant and durable than rubber or PVC lines, especially near hot engine parts.

vs. Stainless Steel: Lower cost while still offering good performance in non-corrosive environments.

Long Service Life: Resists deformation and fatigue better than alternatives.

7. Limitations and Considerations

Corrosion Susceptibility: Bare carbon steel can rust when exposed to moisture. Often coated with zinc (galvanized), paint, or anti-rust oil.

Not for High Pressure: Not suitable for high-pressure fuel injection or brake systems unless specially rated.

Weight: Heavier than aluminum or composite alternatives—less ideal for weight-sensitive applications.

Maintenance: Requires inspection for rust or cracks in humid or salty environments.

8. Surface Treatments and Finishes

To enhance performance and lifespan:

Galvanizing (Zinc Coating): Protects against rust.

Painting or Powder Coating: For aesthetics and additional corrosion resistance.

Anti-Rust Oil: Temporary protection during storage and shipping.

Polishing or Passivation: Improves surface smoothness and flow efficiency.

A Seamless Carbon Steel Engine Low Pressure Pipe is a durable, high-performance tubing solution engineered for reliable fluid and gas transfer in engine systems. Its seamless construction ensures strength and leak resistance, while carbon steel provides a balance of toughness, cost-effectiveness, and machinability. Widely used in automotive, industrial, and mechanical applications, it plays a critical role in maintaining engine efficiency and safety. While it requires protective coatings to resist corrosion, its long lifespan and adherence to global standards make it a preferred choice for OEMs and repair professionals alike. As engine technology evolves, seamless carbon steel pipes continue to be a trusted component in low-pressure fluid systems around the world.

English

English Español

Español русский

русский