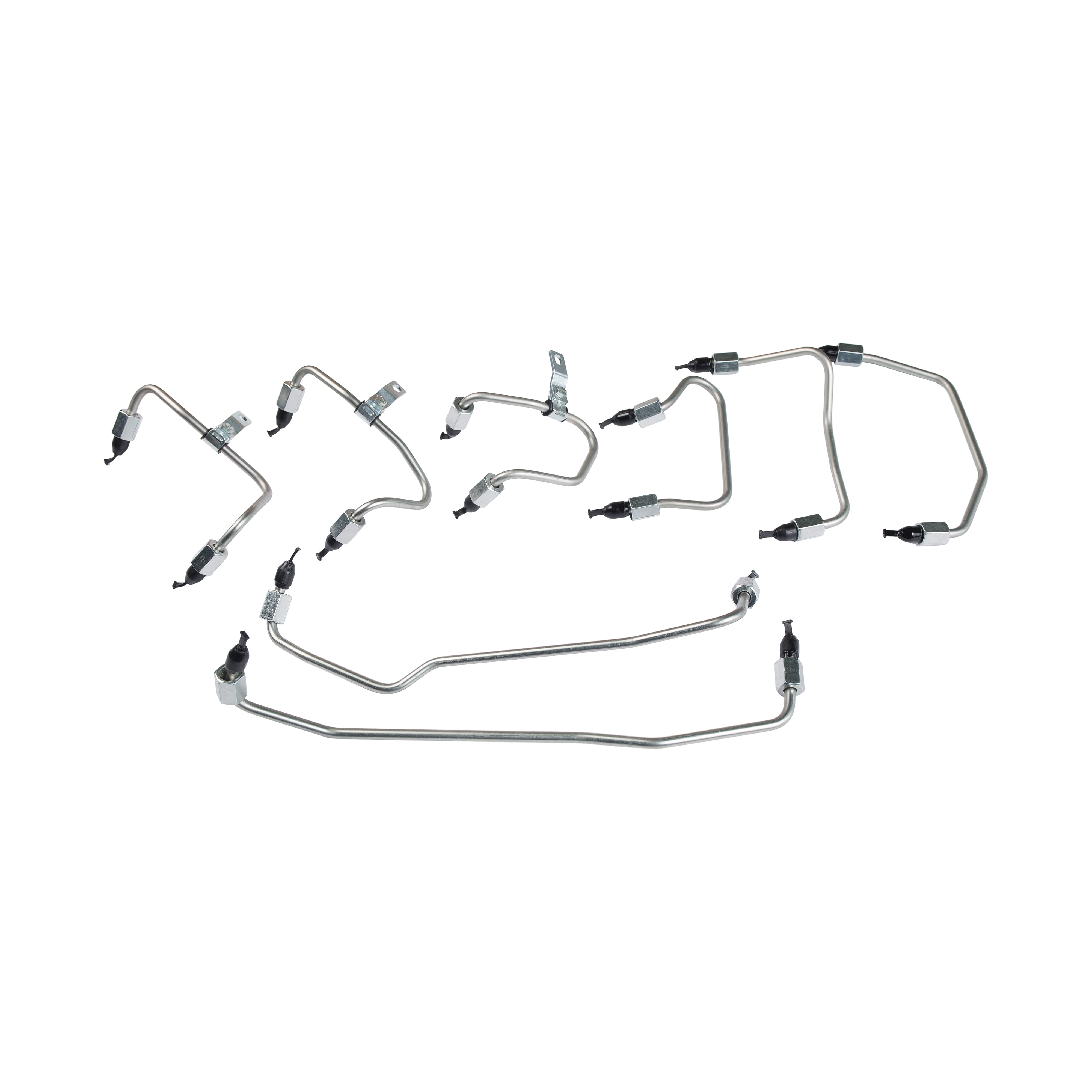

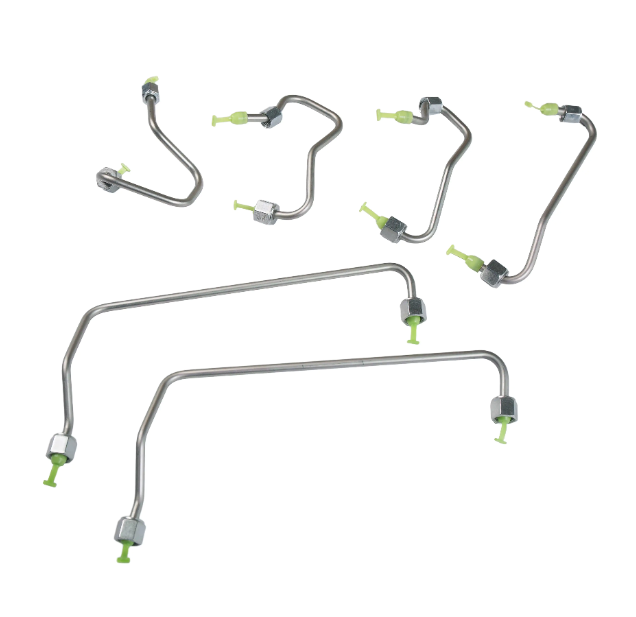

Introduction to Engine Fuel Injection High Pressure Oil Pipes

The engine fuel injection high-pressure oil pipe plays a vital role in delivering fuel to the injectors at the appropriate pressure, ensuring optimal engine performance. Because these components are subject to high levels of pressure and extreme conditions, proper maintenance and upkeep are essential for vehicle reliability and engine longevity. In this article, we will explore the key factors to consider when maintaining and caring for your engine fuel injection high-pressure oil pipes.

The Importance of High-Pressure Oil Pipes in Fuel Injection Systems

High-pressure oil pipes in an engine's fuel injection system are responsible for transporting fuel from the fuel pump to the injectors at the precise pressure needed for efficient combustion. These pipes are typically made from durable materials such as steel or high-strength composites, and they must withstand high-pressure conditions without leakage or failure. Any issue with these pipes can lead to fuel delivery problems, affecting engine performance and fuel efficiency.

Signs of a Faulty High-Pressure Oil Pipe

Before delving into maintenance tips, it's essential to recognize signs of damage or wear in high-pressure oil pipes. Identifying issues early can prevent more severe engine problems. Common signs include:

- Visible leaks around the oil pipes or fuel injectors.

- Decrease in engine performance or power, especially under load.

- Increased fuel consumption due to inefficient fuel delivery.

- Engine misfires or rough idle due to inconsistent fuel pressure.

Steps for Maintaining Engine Fuel Injection High Pressure Oil Pipes

Proper maintenance of engine fuel injection high-pressure oil pipes is essential to ensure that they function efficiently and safely. Here are key steps to follow for upkeep:

1. Regular Visual Inspections

Performing regular visual inspections is one of the simplest ways to maintain high-pressure oil pipes. Check for any visible signs of wear, cracks, or leaks around the oil pipes and connectors. It is essential to inspect the entire length of the pipes, especially near high-stress points such as bends or fittings. If you notice any damage, the pipe should be replaced immediately to avoid further engine problems.

2. Check for Leaks and Tightness

Leaks are a common issue with high-pressure oil pipes, especially where they connect to the fuel injectors or fuel pump. A leak can lead to fuel wastage, performance issues, and even pose a fire risk. Ensure that all connectors and fittings are tightly secured, and check for any fuel or oil spots around the connections. If a leak is detected, it’s crucial to repair or replace the damaged parts immediately.

3. Clean the Pipes and Fittings

Dirt and debris can accumulate on the fuel injection system, including the high-pressure oil pipes and fittings. Over time, this buildup can cause blockages or affect the pressure regulation. Clean the pipes and fittings regularly to ensure smooth fuel flow. Use a clean cloth and mild solvent to wipe down the exterior of the pipes and fittings. Avoid using harsh chemicals that could damage the pipes or seals.

4. Monitor Fuel Pressure

Maintaining proper fuel pressure is vital for the fuel injection system’s performance. A drop in fuel pressure can indicate a problem with the high-pressure oil pipe or fuel system. Regularly monitor fuel pressure using an appropriate gauge, and compare it to the manufacturer’s specifications. If the pressure is too low, it may be due to a blockage or damage in the oil pipes, which would need to be addressed promptly.

Proper Installation of High Pressure Oil Pipes

The installation of high-pressure oil pipes is just as critical as their maintenance. If pipes are installed incorrectly, they may become stressed or damaged during operation, leading to fuel delivery problems. Proper installation steps include:

- Ensure that the pipes are routed correctly, avoiding sharp bends that could weaken the material over time.

- Use the correct torque specifications when tightening fittings to avoid over-tightening, which can damage threads and seals.

- Ensure that all seals and gaskets are in good condition and properly seated to prevent leaks.

- Check for adequate clearance around the pipes to avoid friction with other engine components that could cause wear or damage.

Replacing Damaged High-Pressure Oil Pipes

Even with regular maintenance, high-pressure oil pipes may eventually become damaged or worn beyond repair. In such cases, timely replacement is necessary to ensure optimal engine performance. Here are some key points to consider during replacement:

Select the Correct Replacement Parts

When replacing high-pressure oil pipes, it is essential to choose replacement parts that meet the manufacturer’s specifications. Using inferior or incompatible parts can lead to further engine issues. Consult your vehicle’s manual for the correct part numbers and specifications.

Professional Installation

Replacing high-pressure oil pipes can be complex, especially in modern engines with intricate fuel injection systems. It is often advisable to seek professional assistance for installation to ensure everything is set up correctly. A trained technician can also test the new pipes for leaks and verify proper fuel pressure.

Preventive Measures for Prolonging Pipe Life

To prolong the life of your high-pressure oil pipes and prevent premature wear or damage, consider the following preventive measures:

- Use high-quality fuel to minimize contaminants that could clog or damage the fuel system.

- Perform regular maintenance on the fuel system, including the fuel filter, to prevent debris from entering the pipes.

- Avoid running the engine with low fuel levels, which can introduce air into the system and affect fuel delivery.

- Keep the engine clean to avoid debris or dirt from entering the fuel system and causing damage to the pipes.

Conclusion

Maintaining and properly caring for your engine fuel injection high-pressure oil pipes is crucial for ensuring the performance, safety, and longevity of your vehicle. Regular inspections, proper installation, and timely replacement of damaged parts will help prevent fuel delivery issues and avoid costly repairs. By following these maintenance tips, you can ensure that your engine runs smoothly and efficiently for years to come.

English

English Español

Español русский

русский