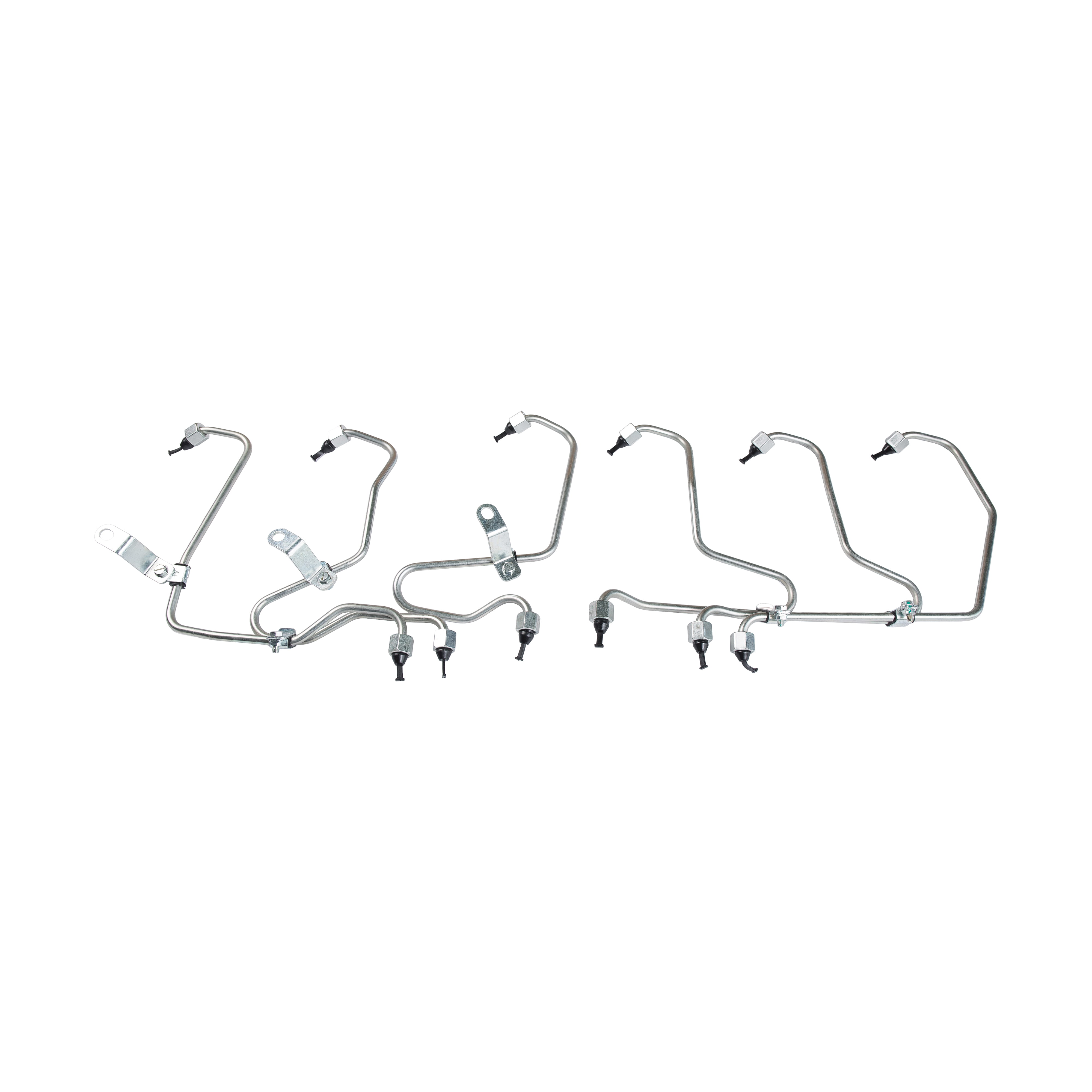

Introduction to Carbon Steel Engine Oil Pipes

Carbon steel engine oil pipes are widely used in automotive and industrial engines due to their high strength, durability, and cost-effectiveness. These pipes are essential for delivering engine oil from the sump to critical components like bearings and camshafts. While carbon steel offers excellent mechanical properties, concerns arise regarding their behavior under high-temperature conditions, which can affect both performance and safety. Understanding the limits of carbon steel pipes under thermal stress is crucial for engine reliability and maintenance.

Material Properties of Carbon Steel

Carbon steel consists primarily of iron and carbon, with varying amounts of manganese, silicon, and other elements depending on the grade. Its mechanical properties, such as tensile strength and hardness, make it suitable for high-pressure applications like engine oil transport. However, carbon steel has a lower corrosion and oxidation resistance compared to stainless steel, which can become a concern at elevated temperatures.

- High tensile strength supports oil flow under high pressure.

- Thermal expansion can cause dimensional changes at elevated temperatures.

- Surface oxidation may occur if protective coatings are not applied.

High-Temperature Effects on Deformation

Engine oil pipes in operation can experience temperatures ranging from 90°C to over 150°C, depending on engine load and oil type. At these temperatures, carbon steel can expand and potentially deform if the material is thin or unsupported. The degree of deformation depends on several factors:

- Wall thickness of the pipe: Thicker walls resist deformation better under thermal expansion.

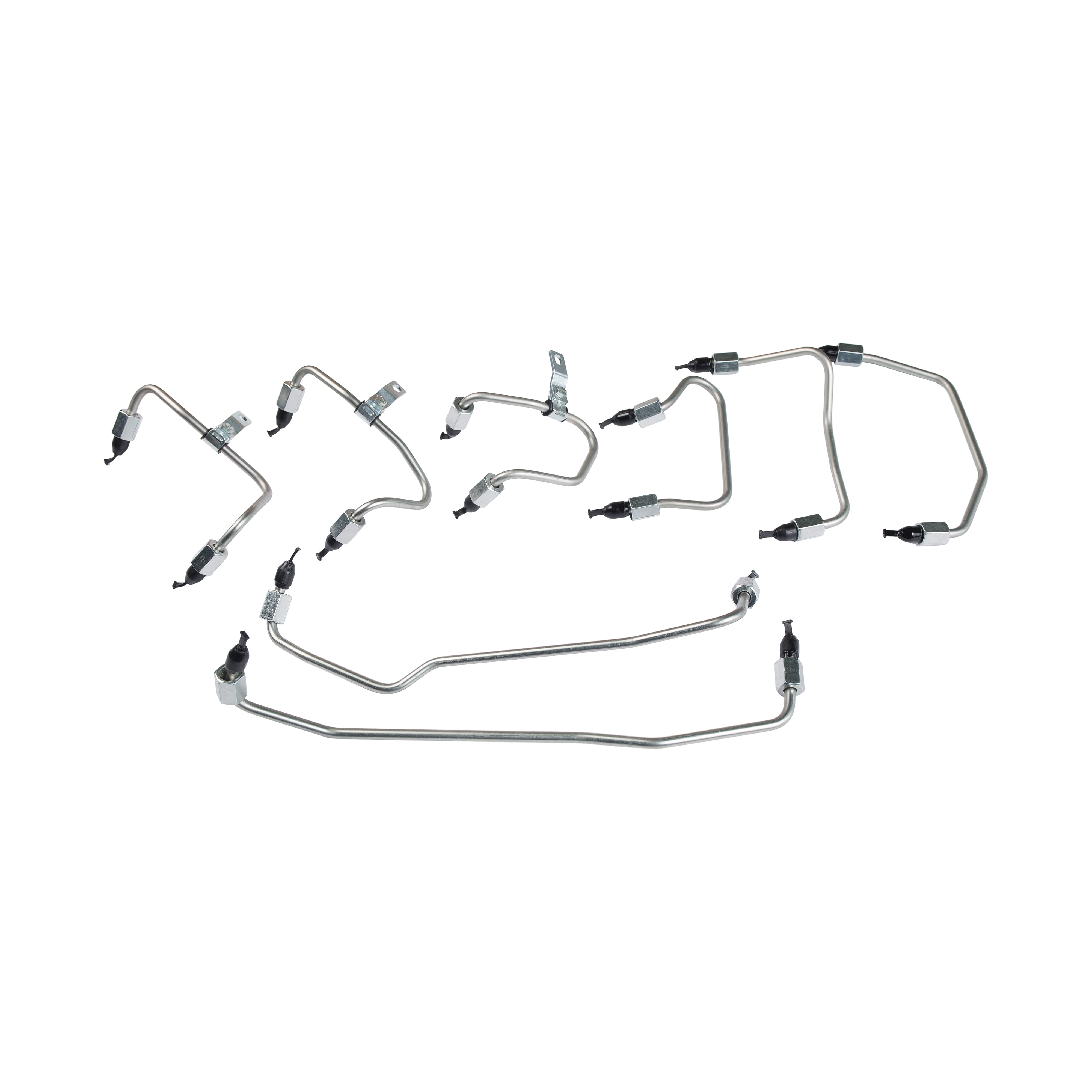

- Pipe geometry: Bends and curves are more susceptible to shape changes than straight sections.

- Mounting and support: Proper clamps and brackets limit thermal movement and reduce stress.

Risk of Leaks Under High Temperatures

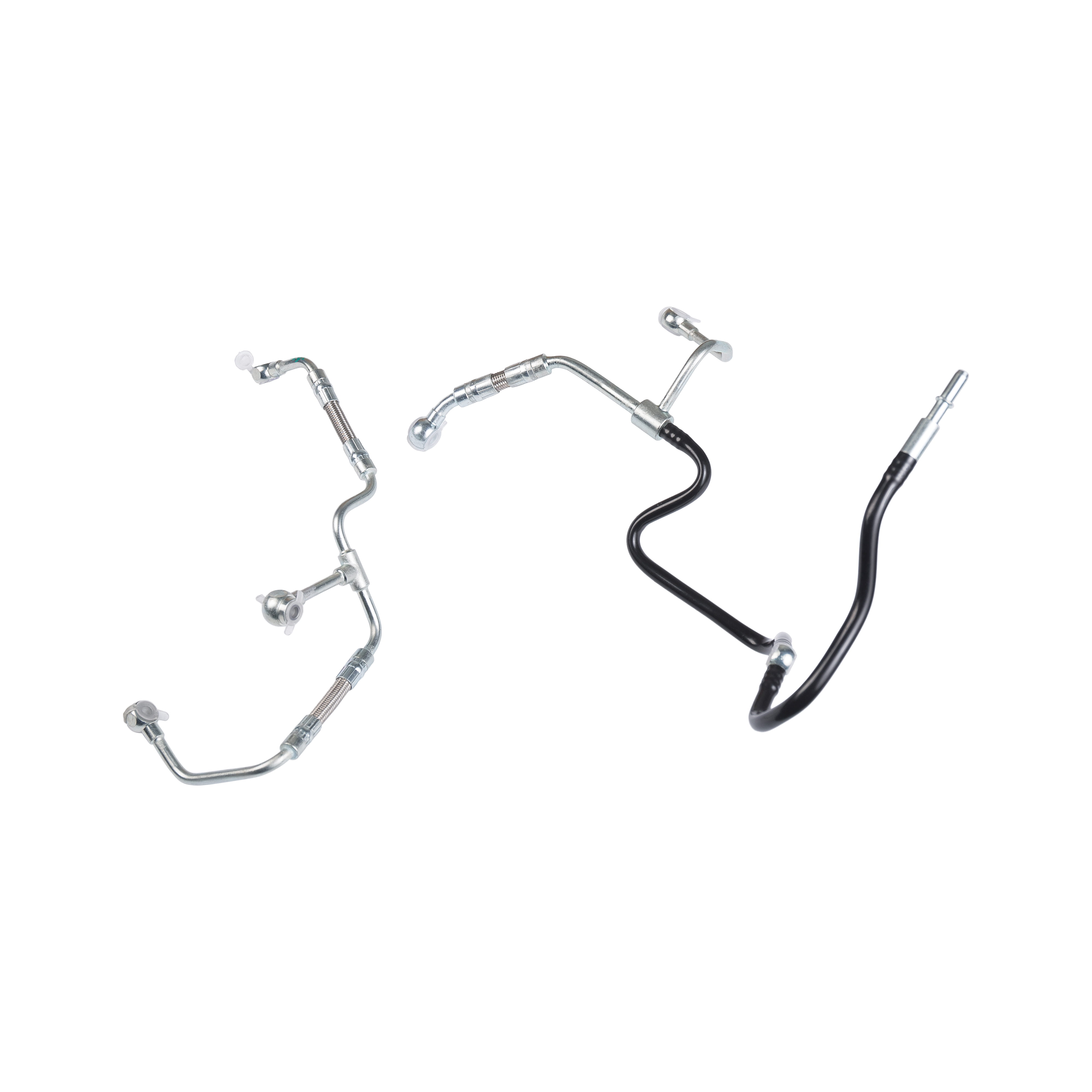

Leaks in carbon steel engine oil pipes typically result from mechanical stress, corrosion, or improper fittings rather than the steel itself melting. High temperatures can accelerate corrosion in uncoated carbon steel, especially in the presence of moisture or engine oil additives. Key factors influencing leaks include:

- Corrosion at joints or bends due to thermal cycling and exposure to oil additives.

- Fatigue cracks in areas where the pipe expands and contracts repeatedly.

- Improper fittings or weakened threads that loosen under heat.

Material Coatings and Treatments

To enhance the performance of carbon steel pipes under high temperatures, manufacturers often apply coatings or treatments. These measures improve corrosion resistance and maintain structural integrity over prolonged use:

- Galvanization or zinc coating to prevent surface oxidation.

- High-temperature paint or enamel for thermal insulation and oxidation prevention.

- Heat treatment to improve hardness and reduce deformation under thermal stress.

Comparing Carbon Steel to Other Materials

While carbon steel is cost-effective and strong, other materials can offer enhanced performance under high temperatures. Common alternatives include:

| Material | High-Temperature Strength | Corrosion Resistance | Cost |

| Carbon Steel | Moderate | Low to Moderate (with coatings) | Low |

| Stainless Steel | High | High | High |

| Aluminum | Moderate | Moderate | Moderate |

Installation and Maintenance Considerations

Proper installation and regular maintenance are critical to prevent deformation or leaks in carbon steel engine oil pipes:

- Ensure correct torque on fittings to prevent loosening under thermal expansion.

- Use clamps and supports to minimize stress on bends and long pipe runs.

- Regularly inspect for signs of corrosion, fatigue cracks, or oil leaks.

- Replace damaged or worn pipes promptly to maintain engine safety and performance.

Conclusion

Carbon steel engine oil pipes are robust and cost-effective, capable of handling high-pressure and moderate-temperature conditions. While they may deform or develop leaks under extreme heat, proper material selection, protective coatings, and careful installation significantly reduce these risks. Regular maintenance and inspections further ensure long-term reliability, making carbon steel a practical choice for many automotive and industrial engine applications.

English

English Español

Español русский

русский